The use of Extruded Aluminum T Slot Profiles has surged in recent years. According to a report by Smith Research, the market for aluminum profiles is projected to reach $60 billion by 2025. This growth is primarily driven by innovations in manufacturing techniques and design flexibility. Experts highlight that T slot profiles allow for easy assembly and adaptability in various projects.

John Anderson, a leading expert in aluminum fabrication, states, “Extruded Aluminum T Slot Profiles offer unmatched versatility for modern engineering applications.” Many industries benefit from this adaptability, allowing for customized solutions tailored to specific needs. However, not all profiles are created equal. Some may lack durability or weight capacity.

Selecting the right Extruded Aluminum T Slot Profile is crucial. It's essential to consider project requirements and industry standards. An incorrect choice can lead to structural failures or increased costs. A careful evaluation of options ensures the best fit for each unique project.

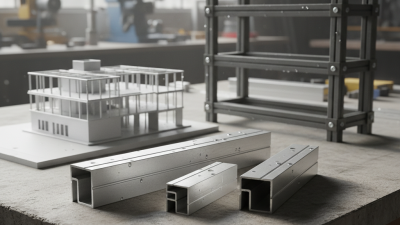

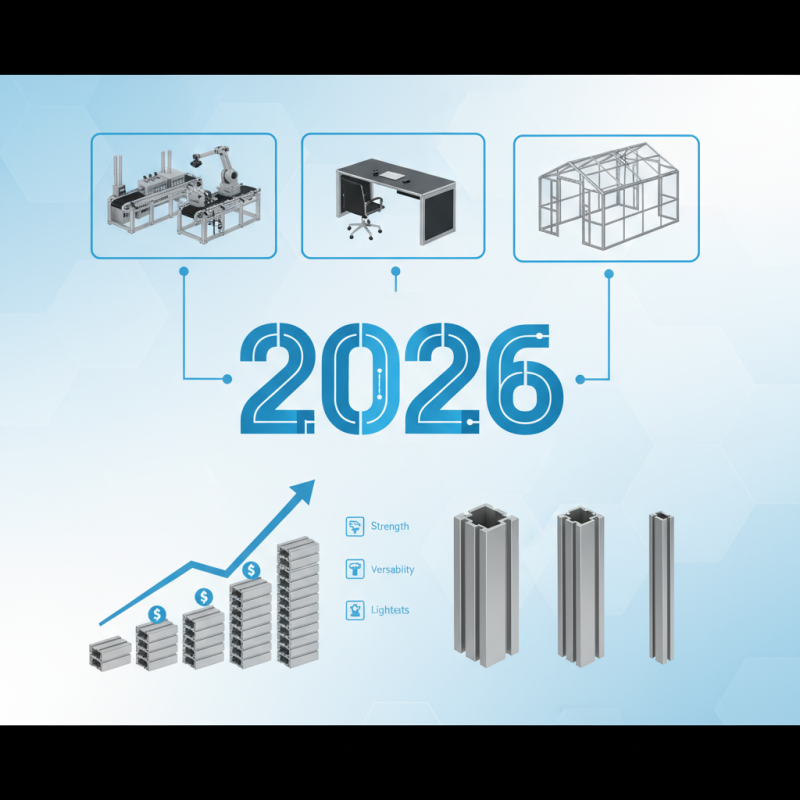

In 2026, the market for extruded aluminum T-slot profiles continues to grow. These profiles are essential for various applications, including framing and assembly systems. The lightweight nature of aluminum makes it an ideal choice for many projects, from machine guards to workstations.

There are several types of extruded aluminum T-slot profiles. Most commonly, you’ll find profiles ranging from 20mm to 80mm in size. The 40mm profile is particularly popular due to its versatility. It strikes a balance between strength and weight, suitable for both light and heavy structures. Data from industry reports indicate that 40mm T-slot frames are utilized in over 60% of modular assembly applications.

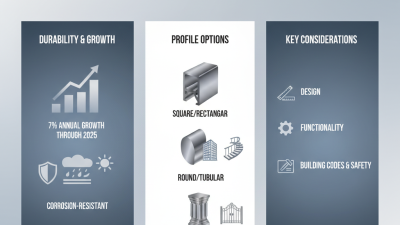

Design flexibility is a key advantage. Designers can easily modify configurations for unique projects. However, not every profile meets every project need. Some may lack the required strength, especially under heavy loads. Consideration of load-bearing capacity is crucial. Data shows that profiles rated for higher loads generally have thicker walls. This trade-off must be evaluated based on specific project requirements.

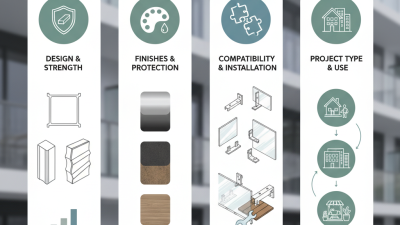

When choosing aluminum T slot profiles, several key features are crucial. Consider the profile size and dimensions that fit your project needs. Standard sizing often simplifies assembly. You should also look for compatible accessories like brackets and connectors. These can enhance structural stability.

The aluminum alloy's strength is vital too. It determines how well the profile can support heavy loads. Consider the finish as well; different finishes affect durability and aesthetics. Some coatings resist corrosion better than others. However, finding the right balance between durability and weight can be challenging.

Another aspect to reflect upon is the ease of assembly. Some profiles are more intuitive than others. You may find that design complexity impacts your workflow. Often, revisiting initial designs helps in understanding potential pitfalls better. While selecting, think about the future needs of your project. Adjustments may be necessary later, so flexibility is key.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Material Grade | Load Capacity (kg) | Surface Finish |

|---|---|---|---|---|---|

| 40x40 | 40 x 40 | 2.5 | 6063-T5 | 200 | Anodized |

| 20x20 | 20 x 20 | 1.2 | 6060-T5 | 100 | Powder Coated |

| 40x80 | 40 x 80 | 4.8 | 6063-T5 | 300 | Natural |

| 80x80 | 80 x 80 | 7.5 | 6063-T6 | 500 | Brushed |

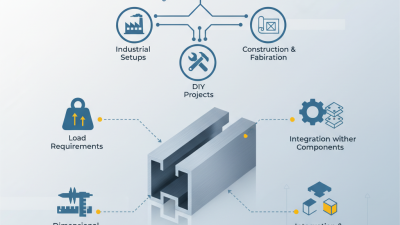

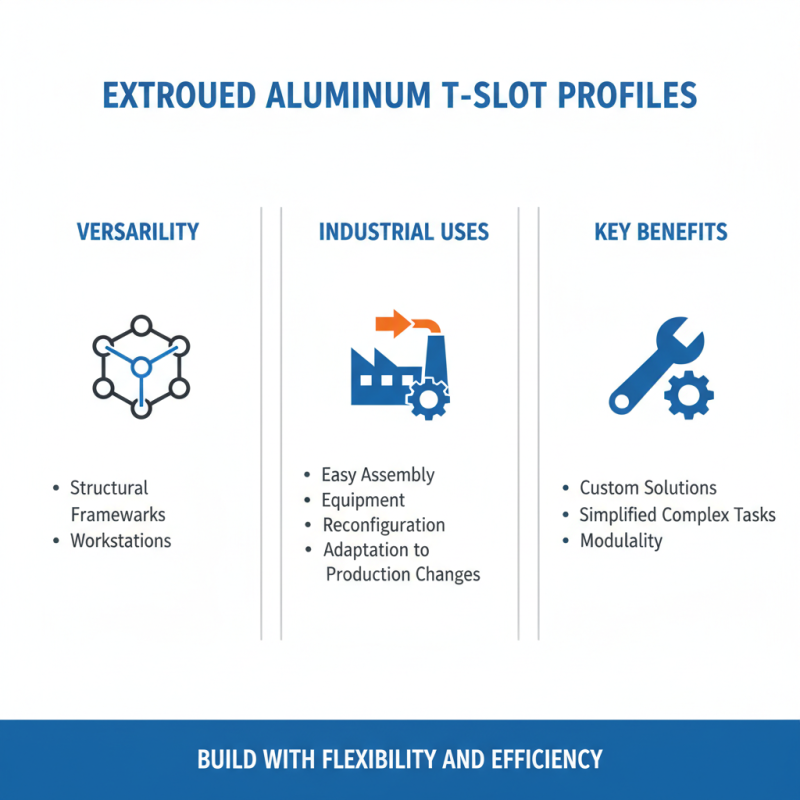

Extruded aluminum T slot profiles are used in a variety of industries. Their versatility makes them popular for building structural frameworks, machinery, and workstations. In manufacturing, these profiles enable easy assembly and reconfiguration of equipment. This is crucial for adapting to changing production needs. Custom solutions are not just a luxury; they simplify complex tasks.

In the robotics industry, T slot profiles create sturdy bases for equipment. The lightweight yet durable nature allows for swift adjustments. Designers appreciate the straightforward assembly process. However, some may overlook how weight distribution affects stability. Pay attention to material thickness to enhance safety and performance.

Tips: Always measure twice before cutting. Precise cuts prevent waste and ensure better fitting. Consider incorporating accessories like brackets and fasteners. They can strengthen your structure significantly. Reflecting on your design choices can lead to improvements in functionality.

When considering T slot profiles in 2026, various brands stand out based on their offerings. The extrusion process influences quality and performance significantly. Industry reports indicate that 70% of engineers prefer aluminum profiles for lightness and durability. T slot profiles are no exception. They provide flexibility in design, making them essential for custom projects.

A recent study found that precise compatibility of T slot sections is crucial for optimal assembly. Misalignments can lead to structural weaknesses, affecting end-user satisfaction. Approximately 30% of users reported issues with fit and finish. This underlines the importance of thorough research before making a purchase. Select profiles that boast high tolerances and proven performance metrics.

In addition, weight-bearing capacity varies widely among different manufacturers. Recent data shows that profiles with a higher weight capacity are preferred for industrial applications. This trend highlights a need for careful evaluation of each brand’s specifications. Balancing cost and quality is a persistent issue. Striking that balance can be challenging but rewarding in the long run.

Aluminum T slot profiles are increasingly popular in various projects due to their versatility and strength. According to a recent industry report, over 70% of manufacturers prefer aluminum profiles for custom machinery and structures. This preference stems from the unique ability of T slots to allow easy adjustments and expansions. Users can modify their configurations without extensive rework. This flexibility proves essential in fast-paced environments.

Moreover, aluminum is lightweight yet robust, which enhances transport and installation efficiency. A study indicated that projects using aluminum T slots saw a reduction in assembly time by up to 30%. This efficiency not only saves labor costs but also accelerates time-to-market. However, despite these benefits, some users report challenges with precise alignment during assembly. T slots can require exact measurements, leading to potential frustrations if not handled carefully.

Choosing aluminum T slots can also present environmental benefits. The material is recyclable, aligning with sustainable practices. A report by the Aluminum Association states that recycling aluminum saves 95% energy compared to producing new aluminum. However, misconceptions about the environmental impact exist. Some may believe that the initial production is entirely eco-friendly, overlooking energy-intensive processes. Therefore, while the benefits are clear, it’s crucial to consider the complete lifecycle of aluminum profiles when planning your project.