In the ever-evolving landscape of construction and architectural design, the Aluminum Handrail Section Profile has emerged as a quintessential element for both safety and aesthetics. According to a report by Grand View Research, the global aluminum railing market is anticipated to reach $4.2 billion by 2025, growing at a CAGR of 5.1%. This surge underscores the increasing preference for aluminum handrails due to their durability, lightweight nature, and resistance to corrosion, which make them ideal for various applications from residential to commercial projects.

As architects and builders seek innovative solutions, selecting the appropriate Aluminum Handrail Section Profile can significantly influence the overall success and appearance of a project. Industry standards, such as those set by the American Society for Testing and Materials (ASTM), provide guidelines for quality and performance, ensuring that these profiles not only meet safety requirements but also aesthetic expectations. In this article, we will explore the top 10 Aluminum Handrail Section Profiles that stand out for their functionality and design, equipping professionals with the knowledge needed to enhance their next project while adhering to industry standards.

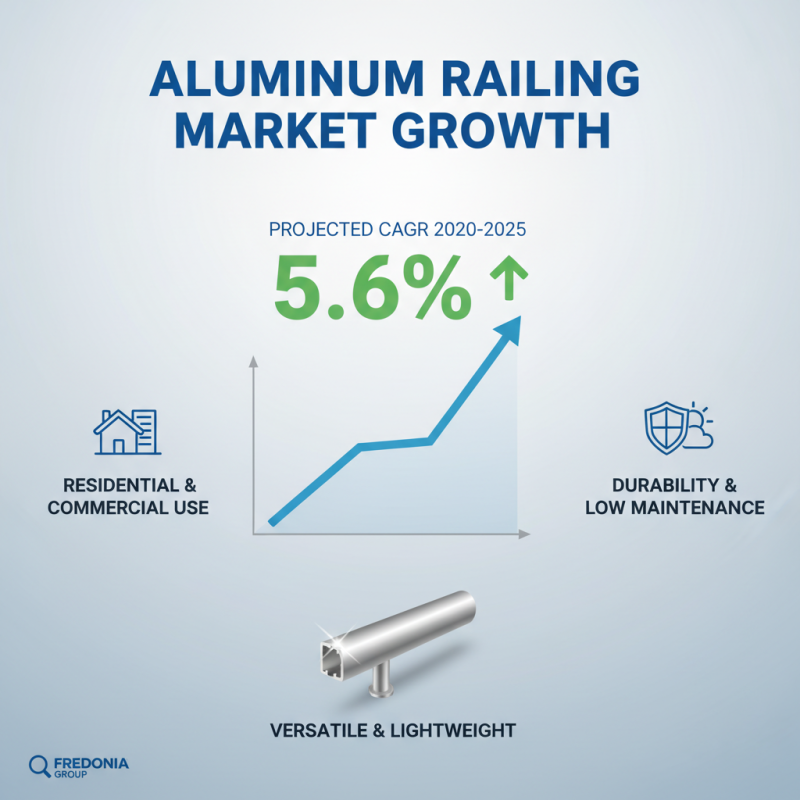

Aluminum handrail section profiles are gaining popularity in various construction and architectural projects due to their durability, lightweight characteristics, and aesthetic appeal. According to the Freedonia Group, the demand for aluminum railing systems is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2020 to 2025. This trend is driven by the increasing use of aluminum in both residential and commercial settings, as it offers a maintenance-free solution that withstands harsh weather conditions.

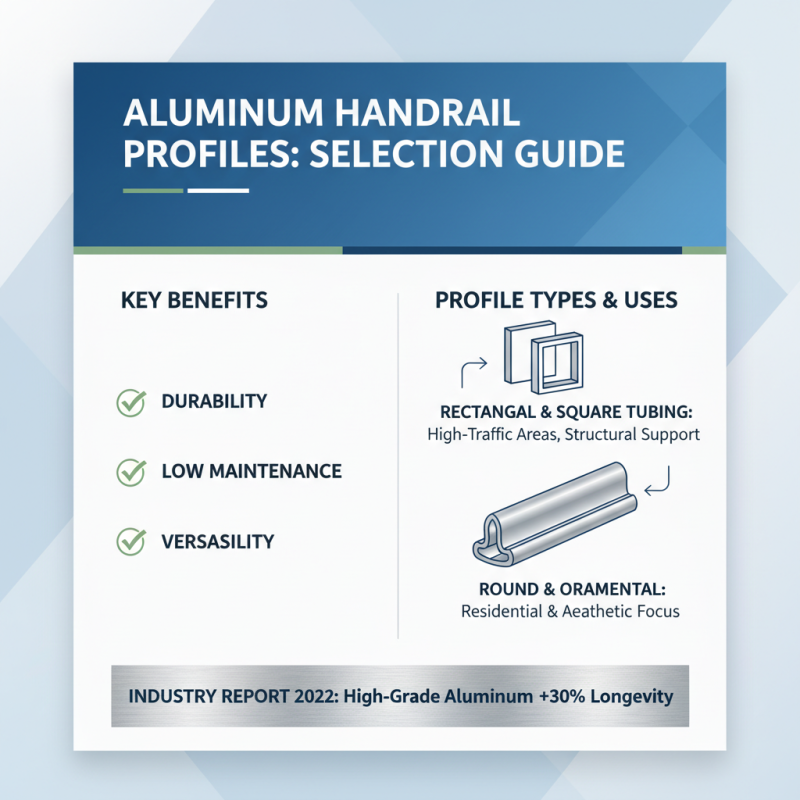

When considering aluminum handrail profiles, design versatility is a key feature. Profiles vary in shape, size, and functionality, providing options that cater to various architectural styles. Common profiles include square, rectangular, and round shapes, which can be solid or hollow based on structural requirements. Industry reports highlight that the adoption of these profiles not only enhances safety but also contributes to aesthetic enhancements in spaces like balconies, decks, and stairways. Furthermore, they can be customized with various finishes and coatings, ensuring they blend seamlessly with their surroundings while offering superior corrosion resistance.

In terms of installation, prefabricated aluminum handrail sections are designed for ease of assembly, significantly reducing labor costs and time. The National Association of Home Builders has indicated that using aluminum railings can lead to a 30% reduction in installation time compared to traditional materials. This efficiency, combined with the long lifecycle of aluminum products, makes them a wise choice for any project focused on sustainability and durability.

When selecting aluminum handrail profiles for your next project, there are several key factors to consider to ensure both functionality and aesthetic appeal. First, the design of the handrail must comply with local building codes and safety regulations, which often dictate specifications such as the height of the handrail and the spacing between balusters. According to the American Society of Civil Engineers, about 30% of falls in construction-related incidents can be attributed to improper railing systems, underscoring the importance of adhering to safety standards.

Another critical factor is the material’s corrosion resistance. Aluminum is naturally resistant to rust, but the finish and coating applied can significantly affect its durability. A study from the Aluminum Association highlights that extruded aluminum profiles, especially those treated with anodization or powder coating, can extend the lifespan of handrails by over 25% compared to untreated options. Additionally, considering the environmental impact of your materials is crucial. As noted in the Global Aluminum Recycling Report, using recycled aluminum can reduce energy consumption in production by up to 95%, demonstrating a shift towards more sustainable building practices.

Lastly, the aesthetic versatility of aluminum profiles should not be overlooked. They come in a variety of finishes and colors, enabling architects and designers to create visually appealing spaces without compromising safety. Customization options are also available, allowing for unique design elements that can enhance the overall look of a structure. As the demand for aluminum handrails grows, understanding these key factors will help ensure that your project not only meets safety and regulatory standards but also stands out in design and durability.

| Profile Name | Height (inches) | Width (inches) | Weight (lbs/ft) | Material Thickness (inches) | Recommended Usage |

|---|---|---|---|---|---|

| Profile A | 36 | 2 | 1.5 | 0.125 | Commercial Railing |

| Profile B | 42 | 3 | 2.0 | 0.125 | Residential Deck |

| Profile C | 48 | 4 | 2.5 | 0.150 | Pool Area |

| Profile D | 36 | 2.5 | 1.8 | 0.120 | Staircase |

| Profile E | 30 | 3.5 | 2.2 | 0.130 | Outdoor Venue |

| Profile F | 42 | 2.2 | 1.6 | 0.140 | Commercial Spaces |

| Profile G | 36 | 3.0 | 2.0 | 0.125 | Event Halls |

| Profile H | 48 | 4.5 | 2.7 | 0.160 | Public Spaces |

| Profile I | 30 | 3.8 | 2.1 | 0.110 | Balconies |

| Profile J | 36 | 2.0 | 1.7 | 0.115 | Private Docks |

When selecting aluminum handrail section profiles for your next project, it’s essential to consider not just aesthetics but also functionality and durability. Among the top recommendations, look for profiles that provide a balance between strength and lightweight characteristics. Designs that incorporate wide bases offer enhanced stability, while sleek, modern profiles can enhance the overall visual appeal of your space.

Tips for choosing the right aluminum handrail profile include evaluating the specific needs of your project. Consider factors like the environment in which the handrail will be installed—coastal areas may require profiles with superior corrosion resistance. Additionally, think about the ease of installation; certain profiles can simplify the process while still adhering to safety standards. Another essential factor is the finish; anodized or powder-coated profiles can withstand weathering, maintaining their look for years regardless of exposure to the elements.

Moreover, assess the handrail sections based on their compatibility with other materials used in your project. Profiles that can easily integrate with glass panels or wood accents can create a more cohesive design. Remember that the right profile not only enhances safety but also elevates the aesthetic of your space, making it crucial to choose wisely.

When selecting aluminum handrail section profiles for your next project, understanding the applications of various profiles is crucial. Aluminum railings are favored in both residential and commercial constructions due to their durability and low maintenance properties. For example, profiles with a higher tensile strength, such as the rectangular and square tubing, are often used in high-traffic areas or locations requiring additional support. According to a 2022 industry report by the Aluminum Association, using high-grade aluminum in handrail profiles can enhance the longevity of constructions by up to 30%.

Different profiles also offer unique aesthetic advantages. For instance, sleek, minimalist designs with round or oval shapes are commonly utilized in modern architecture, providing a contemporary look without compromising safety. Meanwhile, more robust profiles, like channel sections, are ideal for areas where heavy loads are anticipated or where corrosion from environmental factors must be minimized. Recognizing the right profile for your specific needs can drastically improve the functionality and style of your project.

Tip: When choosing an aluminum handrail profile, consider the climate in which it will be installed. Regions with high exposure to moisture may benefit from anodized or powder-coated finishes to prevent corrosion and maintain appearance over time.

Moreover, the ease of installation varies significantly among different profiles. Some geometric shapes are designed to interlock easily, simplifying the assembly process and reducing installation time. According to a recent survey, projects utilizing pre-fabricated modular sections reported a 40% reduction in labor costs. Opt for profiles that enhance both the structural integrity and aesthetic appeal of your construction while optimizing installation efficiency.

When it comes to maintaining aluminum handrail sections, regular upkeep is essential to ensure their longevity and aesthetic appeal. One of the primary maintenance tips is to perform routine inspections for signs of wear, corrosion, or damage. This should include checking for any signs of loose fittings or components, which can compromise the structural integrity of the railings.

Additionally, inspecting for scratches or dents can help you address minor issues before they escalate into more significant problems.

Cleaning aluminum handrails is another crucial aspect of maintenance. It’s advisable to wash them regularly with a mild soap and water solution to remove dirt, grime, and other contaminants. For tougher stains or debris, a non-abrasive cleaner can be used. Avoid harsh chemicals or abrasive pads, as they can damage the protective coating of the aluminum. After cleaning, rinsing the railings thoroughly will help prevent residue buildup.

By adhering to these maintenance tips, you can preserve the quality and appearance of your aluminum handrail sections for many years to come.