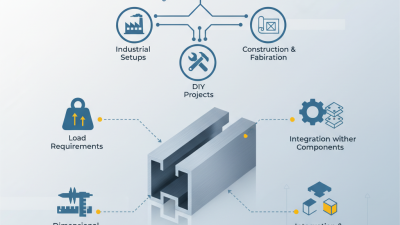

When selecting materials for a project, the choice of profile can greatly influence the final outcome. Experts in the field emphasize the importance of durability, aesthetics, and functionality. John Smith, an expert on aluminum products, notes, "The right profile can transform an ordinary design into a masterpiece." Among various options, the Aluminum High Brightness Anodized Profile stands out for its exceptional qualities.

This profile offers a unique combination of brightness and resistance to wear. Its reflective surface not only enhances the visual appeal but also contributes to energy efficiency. However, some might overlook the necessity of careful handling during installation. User errors can diminish its benefits. It's crucial to adopt best practices to maximize its potential.

Moreover, while the Aluminum High Brightness Anodized Profile is often seen as a premium choice, it's essential to assess its cost-effectiveness for specific projects. Misjudging budget allocations can lead to setbacks. Balancing aesthetics with practicality is key. In conclusion, choosing the right profile can elevate a project’s quality, yet it requires thoughtful consideration and planning.

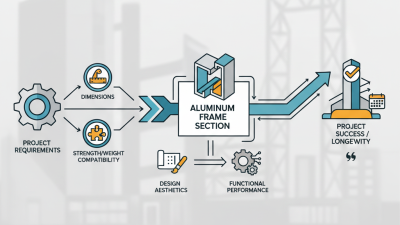

Aluminum high brightness anodized profiles offer significant advantages in construction. These profiles enhance the aesthetic appeal with a sleek, modern finish. According to a recent report by the Aluminum Association, anodized aluminum can increase energy efficiency in building applications by up to 30%. This feature is crucial in reducing overall operational costs. A bright surface reflects more light, which may decrease the need for artificial lighting in commercial spaces.

Moreover, anodized aluminum is highly durable. The anodizing process creates a protective layer, making it resistant to corrosion and scratches. During the product lifecycle, it maintains its appearance with minimal maintenance. However, it’s essential to note that not all anodized coatings are equal. Properties can vary based on the thickness of the anodized layer. Selecting the right thickness is important, as it directly affects performance and longevity.

**Tip:** Always check for certifications and test results when choosing products. Be aware that aesthetic preferences can sometimes overshadow functional attributes. This may lead to future regrets if the chosen profile doesn't meet specific project needs. Ensure you balance design with practicality.

**Tip:** Consult with architects or engineers to assess environmental impact. Not all designs suit anodized aluminum profiles. Each project carries unique requirements that warrant thoughtful consideration.

| Dimension | Benefit | Application |

|---|---|---|

| Lightweight | Easy to handle and install | Residential and commercial buildings |

| Corrosion Resistance | Durability in harsh environments | Outdoor applications, facades |

| High Brightness | Aesthetic appeal, modern look | Interior design, decorative features |

| Low Maintenance | Easier upkeep compared to other materials | Commercial spaces, public buildings |

| Sustainable | Recyclable material | Eco-friendly construction projects |

Anodized aluminum profiles offer impressive durability and corrosion resistance. This makes them ideal for various projects. The anodization process creates a protective layer, enhancing the surface to withstand the elements. Rain, snow, and humidity can wreak havoc on less sturdy materials, but anodized aluminum shines in these conditions.

Corrosion can occur in many forms, often weakening structural integrity. Anodized aluminum combats this effectively. The dense oxide layer formed during anodization acts as a barrier against oxidation. For outdoor applications, this is crucial. Imagine a stylish railing exposed to sunlight and rain daily. Standard materials might corrode; anodized aluminum maintains its brightness and beauty.

However, not all anodized finishes are the same. Some may wear down over time, especially in harsh environments. Regular inspections can help catch any issues early. It’s essential to consider the environment where the aluminum will be used. Subtle environmental factors, like saline air near the coast, can also influence performance. Reflecting on these aspects can guide one to make better choices for their projects.

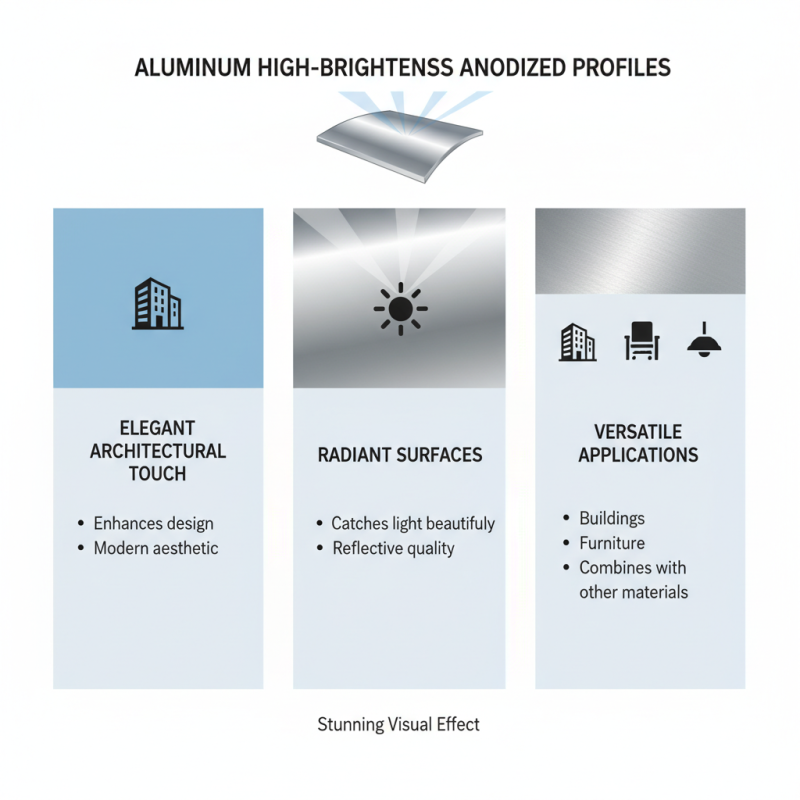

Aluminum high brightness anodized profiles bring an elegant touch to various architectural projects. Their shiny surfaces catch the light beautifully, enhancing any design. Buildings, furniture, and fixtures can achieve a modern aesthetic with these profiles. The reflective quality can create a stunning visual effect, especially when combined with other materials.

However, achieving this brightness requires attention. Not all anodized finishes will look the same under varying lighting conditions. Sometimes, a duller appearance occurs if the anodization process isn't carefully controlled. Minor imperfections in the surface can distract from the overall design. Designers must choose their suppliers wisely and stay involved in the process to ensure the desired outcome.

Incorporating high brightness aluminum profiles can elevate a project but demands careful thought. The aesthetic appeal is undeniable, yet the execution can be tricky. Regular feedback and adjustments can help achieve that perfect shine. A team approach can refine every detail, turning challenges into opportunities for creative solutions. This constant improvement mindset is essential.

Aluminum has become a preferred choice in construction due to its sustainability. Notably, 75% of aluminum ever produced is still in use today. This longevity is crucial in reducing waste. When projects utilize aluminum, they contribute to a circular economy, minimizing the need for new resources.

Recyclability is another significant factor. Aluminum can be recycled indefinitely without losing quality. According to industry reports, recycling aluminum saves up to 95% of the energy required to produce new aluminum. This drastically reduces carbon emissions. Many projects in urban development are now prioritizing aluminum profiles, recognizing the environmental benefits.

However, not all aluminum is created equal. The anodizing process can alter its recycling capabilities. Some finishes may complicate the recycling stream. This highlights the need for careful selection in project materials. Choosing the right anodized profile can foster better health for the planet. Although aluminum has many advantages, education on sustainable practices remains essential.

This bar chart illustrates the recyclability percentage of various materials used in construction projects, highlighting the advantages of Aluminum Anodized Profiles in terms of sustainability.

Aluminum high brightness anodized profiles stand out for their cost-effectiveness. When compared to alternatives like steel or plastic, aluminum offers significant savings. Its lightweight nature reduces shipping costs, making it an attractive choice for many projects. The anodization process enhances durability, extending the lifespan of the profiles. They resist corrosion and require less maintenance over time, which is critical for long-term projects.

Using aluminum also appeals to eco-conscious builders. Aluminum is highly recyclable, and its production has a lower carbon footprint than that of many materials. However, it’s important to weigh these benefits against potential drawbacks. For example, while anodized aluminum adds surface durability, it can be more expensive upfront than untreated alternatives. This requires careful budgeting.

In some cases, specific applications may not favor aluminum due to structural limitations. Heavy machinery setups might require more robust materials. Thus, understanding the project requirements is essential. The choice may not always be straightforward. Balancing cost, functionality, and aesthetics can lead to valuable insights for future designs.