Aluminium Angle Extrusion Slats offer numerous advantages for both industrial and DIY projects. These slats are not only lightweight but also incredibly durable. Their unique properties make them a preferred choice in various applications, including construction and manufacturing.

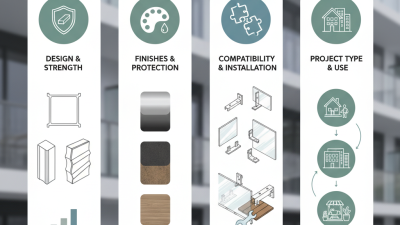

One notable feature of Aluminium Angle Extrusion Slats is their versatility. They can be used in frames, supports, or even decorative elements. This adaptability makes them suitable for many project types. Additionally, their resistance to corrosion ensures longevity, reducing the need for frequent replacements. However, it’s essential to choose the right size and design to maximize their effectiveness.

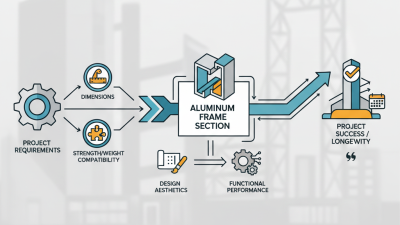

While Aluminium Angle Extrusion Slats are popular, there can be challenges in sourcing and installation. Misjudging dimensions can lead to project delays. Ensuring proper installation is crucial for stability and safety. Despite these potential pitfalls, the benefits outweigh the drawbacks for many applications. With careful planning, Aluminium Angle Extrusion Slats can significantly enhance your projects.

Aluminium angle extrusion slats offer a range of compelling benefits in construction projects. They are lightweight yet strong, making them ideal for various structural applications. This combination enhances the integrity of buildings while reducing labor costs. Their versatility allows for easy customization, fitting into different designs and layouts seamlessly. Projects often succeed with the use of aluminum slats, but miscalculations can lead to mismatched dimensions.

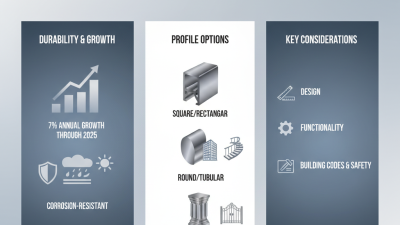

Durability is another significant benefit. Aluminium resists corrosion, ensuring the longevity of structures. This resistance is crucial, especially in environments with harsh weather conditions. However, improper installation can diminish these benefits. Regular maintenance is still necessary to maximize performance over time.

Cost-effectiveness also plays a key role. Although the initial investment may seem high, aluminium slats save money on repairs in the future. They often require less maintenance compared to other materials. Projects utilizing these slats can encounter challenges, especially if unanticipated structural changes arise. Yet, with proper planning, the advantages outweigh the drawbacks.

Aluminium angle extrusions are known for their exceptional durability and strength. This material can withstand harsh weather conditions, making it a preferred choice for construction projects. According to a 2022 industry report, aluminium extrusions have a tensile strength of 90 to 580 MPa, which is significantly higher than many alternative materials. This means they can handle heavy loads without deforming.

The corrosion resistance of aluminium is another critical factor contributing to its longevity. Unlike steel, aluminium does not rust. A study in 2021 revealed that well-finished aluminium extrusions can last up to 30 years in outdoor environments. This durability reduces the need for frequent replacements, ultimately saving costs over time. However, improperly finished extrusions may still suffer from surface damage.

One might question whether aluminium angles truly outperform other materials in all situations. For instance, if not properly maintained or inspected, they could show signs of wear. While the advantages are clear, it’s essential to recognize that using high-quality aluminium is vital. Quality control in the manufacturing process can significantly impact performance. The right choice offers strength paired with resistance to deterioration.

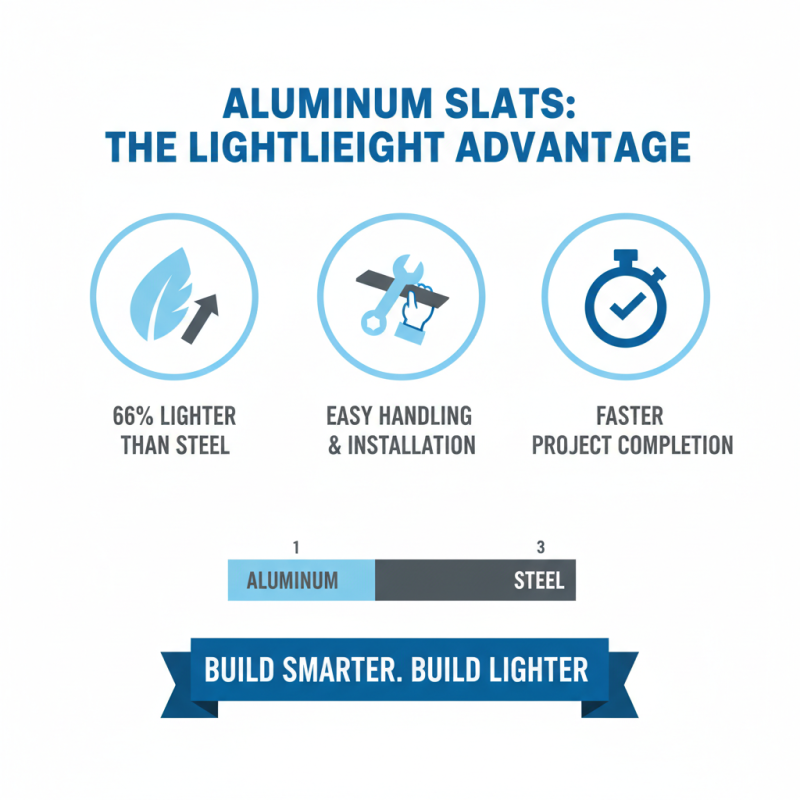

Aluminium slats have gained popularity due to their lightweight characteristics. By utilizing aluminium angle extrusion slats, projects can benefit from easy handling and installation. This is especially crucial in construction, where reducing weight can lead to faster project completion. According to a report by the Aluminium Association, aluminium is 66% lighter than steel, making it an ideal choice for various applications.

Versatility is another major advantage of aluminium slats. They can be used in numerous fields, from furniture design to architectural elements. The flexibility of aluminium allows it to be adapted easily to different designs and requirements. Research shows that the use of aluminium in innovative designs increased by 30% in the last five years. However, it's important to acknowledge that some projects may require additional testing for durability.

While aluminium slats offer many benefits, there are challenges to consider. For example, while they resist corrosion, specific finishes might be necessary for prolonged exposure to harsh environments. It’s essential to weigh these factors when selecting materials. Balancing lightweight benefits and potential limitations is crucial for optimal project outcomes.

Aluminium angle extrusion slats are gaining popularity in various projects. Their cost-effectiveness is a significant advantage. Projects in construction, manufacturing, and DIY benefit from these materials. The initial investment is often lower than other options. This can lead to better budget management.

The lightweight nature of aluminium makes it easier to work with. Transporting materials incurs lower shipping costs. Installation is typically faster, saving labor expenses. These slats require minimal maintenance, which further reduces long-term costs. However, some may overlook durability concerns. While aluminium resists corrosion, it can bend or dent easily. Understanding this property is crucial for long-lasting outcomes.

Choosing aluminium angle extrusion slats might seem straightforward. Yet, it demands thoughtful consideration. Not every project might benefit equally. Evaluating specific needs and conditions is essential. Balancing cost and quality will lead to better results. A thoughtful approach can make all the difference.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Durability | Aluminium angle extrusion slats are resistant to corrosion and wear, ensuring a long lifespan. | Reduced replacement costs due to longer durability. |

| Lightweight | Easier to handle and install compared to heavier materials. | Lower labor costs due to easier installation. |

| Versatility | Suitable for a wide range of applications in various industries. | Flexible use across different projects promotes efficient material use. |

| Sustainability | Aluminium is recyclable, minimizing environmental impact. | Potential cost savings from recycling processes. |

| Aesthetic Appeal | Modern and sleek appearance enhances design aesthetics. | Higher perceived value can justify project budgets. |

| Low Maintenance | Requires minimal upkeep compared to other materials. | Savings on ongoing maintenance costs. |

| Strength | High strength-to-weight ratio allows for efficient designs. | Fewer materials needed for structural support. |

| Custom Design | Easily customizable to meet specific project requirements. | Avoids costs associated with stock materials. |

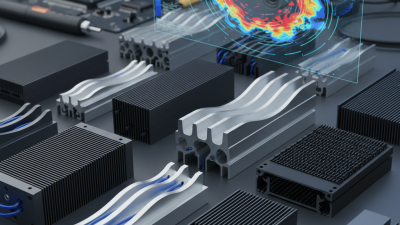

| Thermal Conductivity | Excellent thermal conductivity makes it suitable for various applications. | Can lead to energy-saving benefits in thermal applications. |

| Cost Efficiency | Affordable material with competitive pricing in the market. | Helps keep overall project costs within budget. |

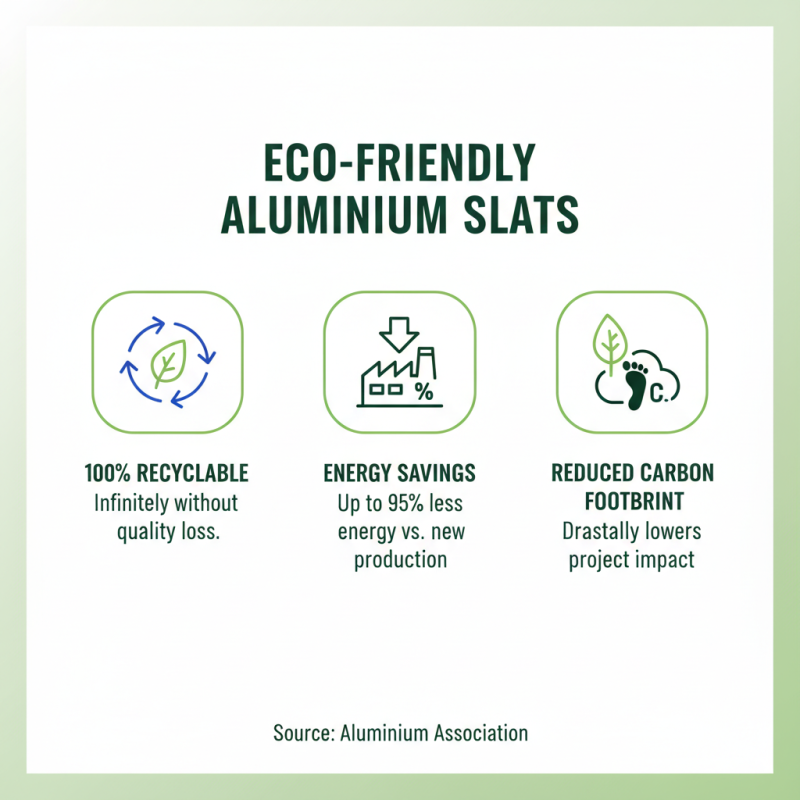

Aluminium angle extrusion slats offer significant eco-friendly advantages that appeal to sustainable project designs. Unlike many alternatives, aluminium is 100% recyclable without losing quality. According to the Aluminium Association, recycling aluminium saves up to 95% energy compared to new production. This means using aluminium slats could drastically reduce the carbon footprint of construction projects.

Moreover, the lightweight nature of aluminium slats leads to lower transportation emissions. Their durability also plays a role in sustainability. A report from the International Aluminium Institute highlights that aluminium structures have a longer lifespan, reducing the need for frequent replacements. This longevity means fewer resources are consumed over time for maintenance and manufacturing.

However, even with these benefits, there are challenges. The initial energy consumption during production remains high. Depending on the source, this can vary. Some manufacturers use renewable energy, but not all do. It’s essential to verify these practices to ensure that sustainability claims are met. Additionally, while recycling rates are impressive, there's still a gap in collection and processing in certain regions. Addressing these issues can lead to a more sustainable future for aluminium use in construction.