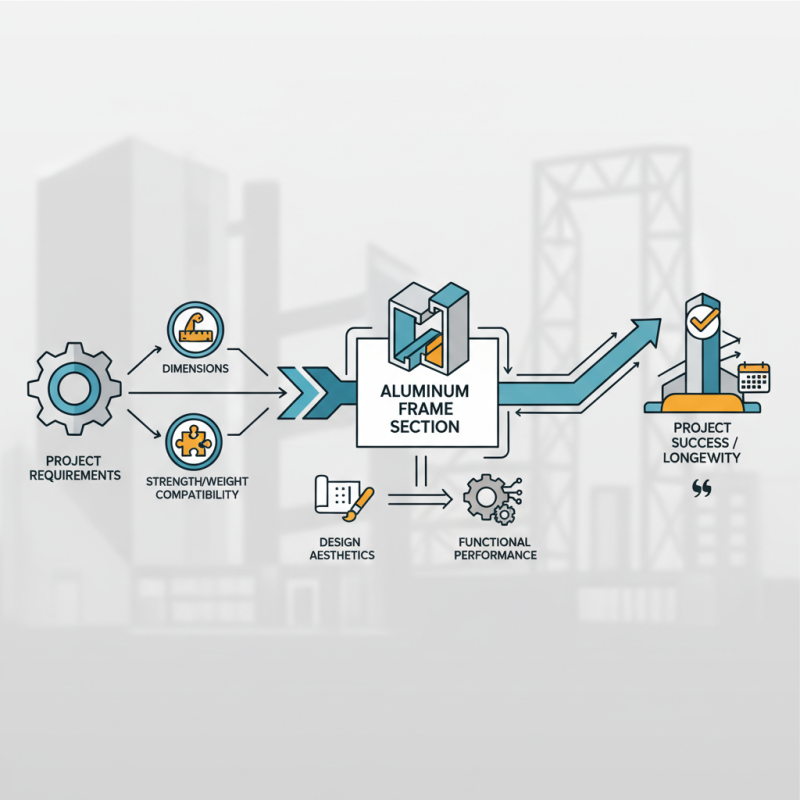

Selecting the right Aluminum Frame Section Profile is crucial for the success of any construction or manufacturing project. As industry expert John Smith, a leading engineer in structural design, aptly states, "The right profile not only enhances the structural integrity but also optimizes cost efficiency and production time." This statement underscores the importance of carefully considering various factors when choosing the ideal aluminum frame section for specific applications.

When evaluating Aluminum Frame Section Profiles, several key elements come into play, including dimensions, weight, strength, and compatibility with other materials. Understanding the unique requirements of your project is essential to making an informed decision. The interplay between design aesthetics and functional performance can significantly impact not only the usability of the final product but also the overall project success. In this article, we will explore the essential considerations that will assist you in selecting the best Aluminum Frame Section Profile tailored to your needs, ensuring that your project stands the test of time while maintaining its intended purpose.

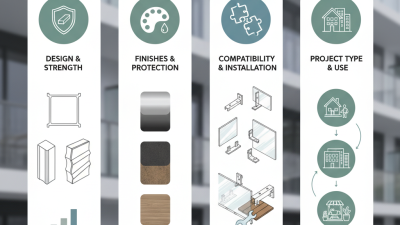

When starting a project that requires an aluminum frame, it's essential to understand the different types of aluminum frame section profiles available. Each profile serves a specific purpose and caters to varying structural needs. Common profiles include square and rectangular tubes, which provide sturdy frameworks suitable for a wide range of applications. These shapes are known for their strength and rigidity, making them ideal for projects that demand durability and support.

Another type of profile is the C-channel, which offers great versatility in design and can be used as a structural support in various configurations. The T-slot profile is also gaining popularity, particularly in modular construction. Its slot design allows for easy assembly and disassembly, enabling quick adjustments and modifications to the structure. Understanding the characteristics and applications of these profiles will assist in making informed decisions tailored to your project's requirements.

| Profile Type | Application | Dimensions (mm) | Weight (kg/m) | Strength (MPa) |

|---|---|---|---|---|

| Square Tube | Frameworks, supports | 20 x 20 | 1.5 | 200 |

| Rectangular Tube | Heavy-duty applications | 30 x 20 | 2.0 | 250 |

| L-Shape Angle | Braces, corner joints | 25 x 25 | 1.8 | 210 |

| C-Channel | Beams, railings | 40 x 20 | 3.0 | 230 |

| T-Slot Profile | Modular structures | 20 x 40 | 2.5 | 240 |

When selecting an aluminum frame section profile for your project, several key factors must be considered to ensure optimal performance and suitability. First, evaluate the specific mechanical properties required for your application. This includes assessing the strength-to-weight ratio, stiffness, and durability of the aluminum alloy. Depending on the intended use—be it structural support, aesthetic appeal, or both—the choice of profile can significantly impact overall project integrity and longevity.

Another crucial aspect is the profile's geometry. Different shapes, such as square, rectangular, or custom designs, can offer varying degrees of strength and load-bearing capabilities. It’s essential to understand the loads the frame will endure, including static and dynamic forces. Furthermore, consider the ease of fabrication and assembly; some profiles may lend themselves better to modular designs, simplifying construction and reducing costs. By carefully weighing these factors, you can select an aluminum frame section profile that aligns perfectly with your project’s requirements.

This chart compares different aluminum frame section profiles across two key factors: weight and load capacity. Choosing the right profile is crucial for project success, and understanding these metrics can help inform your decision.

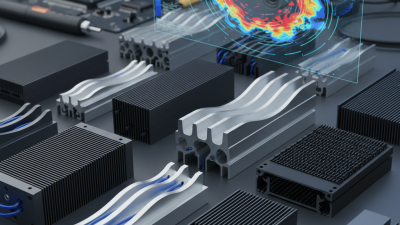

When selecting an aluminum frame section profile for your project, analyzing the balance between strength and weight is crucial. Aluminum, known for its lightweight characteristics, offers an excellent strength-to-weight ratio, making it an ideal choice for various applications. However, it is essential to consider the specific requirements of your project. For structures that demand high strength, such as industrial frames or scaffolding systems, opting for a profile with a higher thickness or a more robust geometric shape can enhance structural integrity while still maintaining manageable weight.

Weight considerations also play a significant role, especially in applications where mobility or transportability is essential. In cases like portable structures or temporary setups, using thinner profiles can reduce overall weight, making assembly and disassembly more efficient. Nevertheless, it’s important to ensure that the chosen profile can withstand the anticipated loads and stresses without sacrificing safety. Compromising on strength for weight can lead to potential failures, so conducting load-bearing calculations and stress tests will help in making a well-informed choice that aligns with the project’s goals.

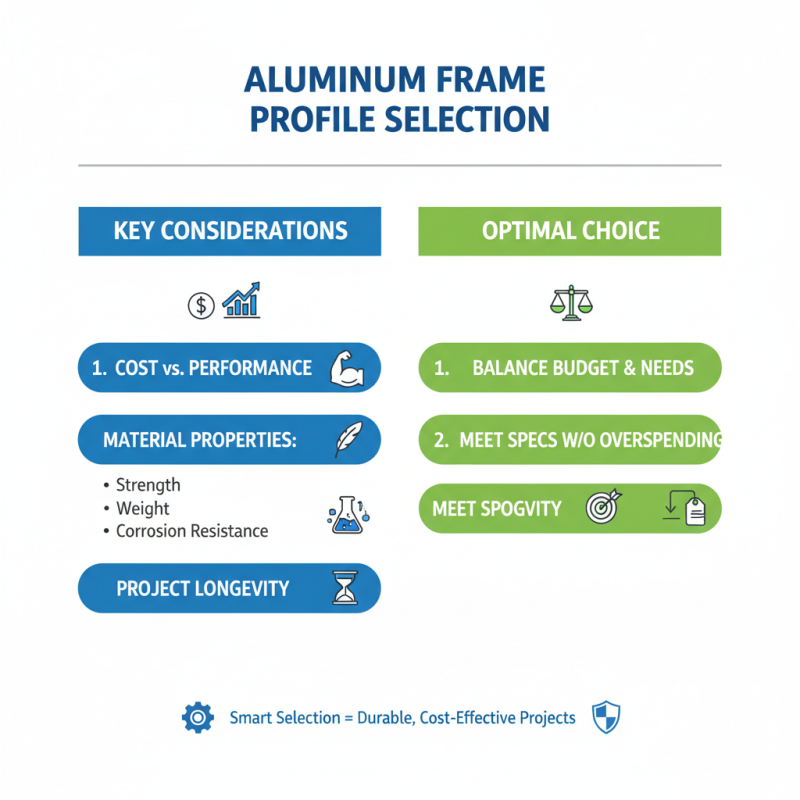

When selecting an aluminum frame section profile for your project, one of the most critical aspects to consider is the balance between cost and performance. Aluminum profiles vary significantly in terms of their material properties, including strength, weight, and corrosion resistance, which can directly influence both the project’s overall cost and its longevity. Performance may not always equate to a higher price; sometimes, a more cost-effective profile can meet the structural requirements without compromising quality.

Evaluating the cost versus performance of aluminum frame profiles involves analyzing several factors, including the specific application, load-bearing requirements, and environmental conditions. For instance, a lightweight profile may reduce the up-front costs in transportation and handling, but it should still meet the necessary performance standards for safety and durability. Additionally, assessing the lifecycle costs is important; a slightly higher initial investment might result in lower maintenance expenses and higher performance over time. Understanding these dynamics will empower decision-makers to choose the appropriate aluminum frame that aligns with their project’s budget and performance goals.

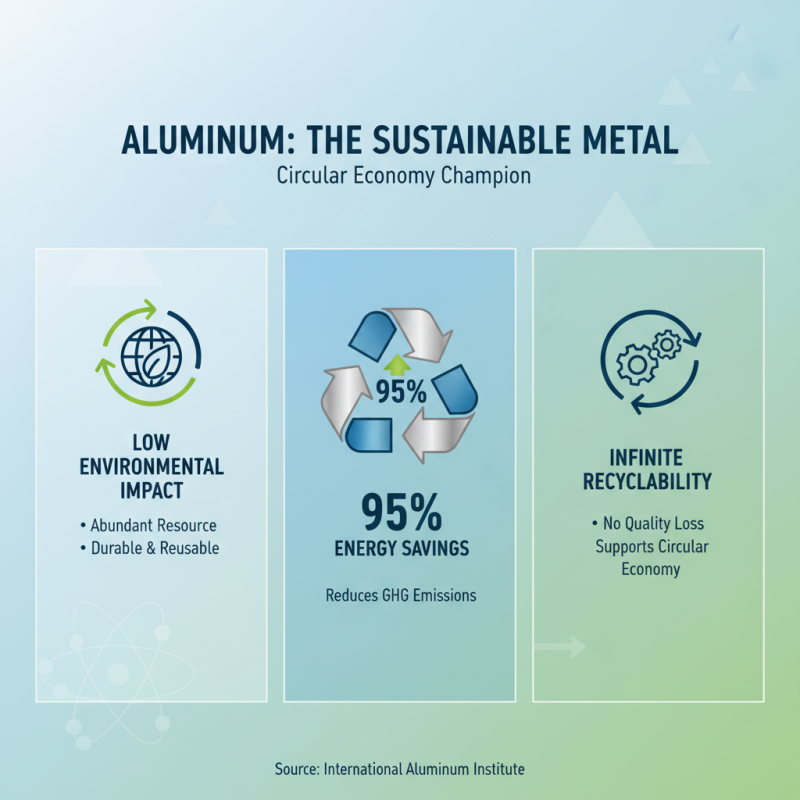

Aluminum has become one of the preferred materials in various industries, largely due to its sustainability and low environmental impact. According to a study by the International Aluminum Institute, recycling aluminum can save up to 95% of the energy required to produce new aluminum from raw materials. This energy efficiency not only reduces greenhouse gas emissions but also underscores the circular economy model, where aluminum can be reused repeatedly without loss of quality.

Moreover, the production of aluminum has seen significant advancements to minimize environmental impact. For instance, the adoption of sustainable practices in mining and refining processes has led to a notable decrease in carbon footprints. The Global Aluminum Industry's commitment to reducing emissions is reflected in their target to achieve a 50% reduction in carbon emissions by 2030 compared to 2005 levels. This illustrates that choosing aluminum for projects not only aligns with current sustainability goals but also supports responsible sourcing and manufacturing practices that contribute positively to the environment. Ultimately, selecting aluminum frame section profiles emphasizes an ecological approach, benefitting both project outcomes and our planet.