Choosing the right Aluminum Railing Extrusion for your project is a critical decision that can greatly impact the durability, aesthetics, and overall performance of your railing system. According to a recent market report by Grand View Research, the aluminum railing market is projected to grow significantly, with an expected CAGR of 6.5% from 2021 to 2028. This growth is driven by the increasing demand for lightweight yet robust building materials in both residential and commercial applications. Industry expert Dr. John Miller, a renowned authority on extrusion technology, emphasizes, "The choice of aluminum extrusion not only determines the structural integrity of the railing but also influences maintenance costs and safety features."

In the context of residential and commercial construction, the distinct characteristics of Aluminum Railing Extrusion play a pivotal role in design and functionality. With its resistance to corrosion, low weight, and customizable nature, aluminum has become a preferred material for many architects and builders. However, understanding the various profiles, finishes, and manufacturing techniques is essential for optimizing performance and ensuring aesthetic alignment with the overall design of the project. This article aims to guide you through the essential factors to consider when selecting the best Aluminum Railing Extrusion, ensuring that your investment aligns with your project's goals and industry standards.

Aluminum railing extrusions are an essential element in modern construction and design, providing both functionality and aesthetic appeal. These extrusions are designed to create strong, lightweight railings suitable for various applications, from residential decks to commercial building facades. One of the key benefits of aluminum railing extrusions is their resistance to corrosion, making them ideal for outdoor use where they can withstand harsh weather conditions without deteriorating over time. Additionally, their durability ensures a long lifespan, reducing the need for frequent replacements and maintenance.

When choosing the right aluminum railing extrusion for your project, it's important to consider the overall design and intended application. For instance, the thickness and profile of the extrusion directly influence its strength and visual impact. A well-chosen extrusion will enhance the project’s architectural style while providing the necessary safety and support.

Tips: To ensure you select the optimal aluminum extrusion, assess the specific requirements of your project, including load-bearing capacities and aesthetic preferences. Additionally, consult with industry experts or manufacturers to learn about the latest advancements and customization options available for aluminum railings. Prioritizing high-quality materials will not only enhance the durability of your installation but also elevate its overall look.

When selecting the best aluminum railing extrusion for your project, it is crucial to evaluate the specific requirements of your application. Consider aspects such as the environmental conditions, intended use, and aesthetic preferences. For example, if the railing will be installed in a coastal area, it should be resistant to corrosion and have a protective finish that withstands harsh conditions. Assessing these factors will help narrow down your choices and ensure the selected extrusion meets both safety standards and durability expectations.

**Tips:** Always check for compliance with local building codes and regulations, as this can save you time and money in the long run. Additionally, think about the installation process: some extrusions may require special tools or techniques which could influence your decision.

Another critical consideration is the design and style of your railing system. Aluminum railings come in various shapes and profiles, impacting not only the visual appeal but also the structural integrity. Evaluate the overall design of your space and how the railing will complement it. Moreover, don’t overlook the importance of color and finish, as these choices can significantly affect the ultimate look of your project.

**Tips:** When in doubt, consult with a professional to discuss design possibilities—they can provide valuable insights tailored to your unique project requirements.

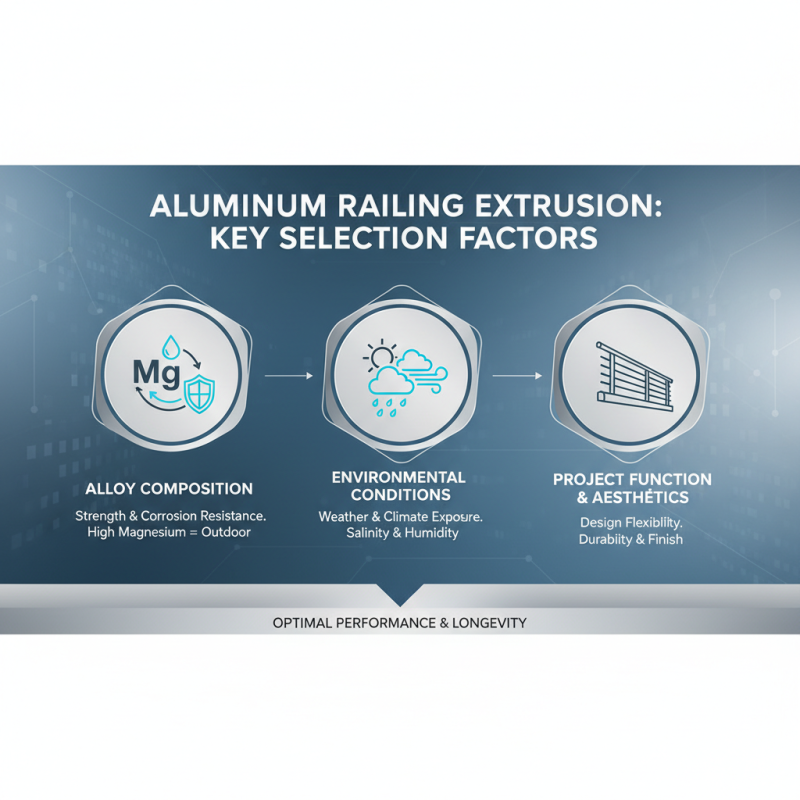

When selecting the best aluminum railing extrusion for your project, it’s important to consider several key factors that can influence both the functionality and aesthetics of your final product. One major aspect to evaluate is the alloy composition of the aluminum. Different alloys offer varying levels of strength, corrosion resistance, and workability. For instance, alloys with higher magnesium content provide excellent corrosion resistance, making them ideal for outdoor applications. Understanding the environmental conditions the railing will face can help determine the most suitable alloy for your needs.

Another critical factor is the design and profile of the aluminum extrusion itself. The shape and size of the profile not only affect the installation process but also the overall look and feel of the structure. Consider whether sharp angles or rounded edges align better with your design vision and ensure that the selected profile can accommodate the required load-bearing capacity. Additionally, it's vital to assess whether the extrusion allows for easy integration with other components of your railing system, such as posts and infill options, to facilitate a seamless construction process. Careful attention to these details will lead to a more successful railing project.

When selecting the best aluminum railing extrusion for your project, it's crucial to understand the different types available and their respective benefits. Aluminum railing extrusions can generally be categorized into structural and decorative types. Structural extrusions are designed for strength and durability, making them ideal for applications requiring robust support, such as commercial and industrial settings. These options typically feature thicker walls and enhanced corrosion resistance, ensuring longevity even in harsh environments.

On the other hand, decorative aluminum railing extrusions focus on aesthetics while still providing adequate support. These are commonly used in residential applications, where design plays a significant role. Available in various shapes and finishes, decorative extrusions can complement the architectural style of a home or building. When comparing these options, consider the intended use, local climate conditions, and the desired look for your project. Ultimately, balancing functionality with style will help you make the best choice for your aluminum railing needs.

| Type of Extrusion | Weight (lbs/ft) | Load Capacity (lbs) | Corrosion Resistance | Cost (per ft) |

|---|---|---|---|---|

| Standard Aluminum | 1.5 | 200 | Moderate | $6.00 |

| Anodized Aluminum | 1.4 | 250 | High | $7.50 |

| Powder Coated Aluminum | 1.6 | 300 | Very High | $8.00 |

| Marine Grade Aluminum | 1.8 | 350 | Excellent | $10.00 |

When installing aluminum railings, careful attention must be given to both the environment and the application to ensure long-lasting performance. The installation process starts with ensuring that the surfaces are clean and free from obstructions. It is essential to follow the manufacturer’s guidelines regarding spacing and anchoring to guarantee structural integrity. Proper alignment during installation can prevent future issues, such as misalignment or instability, that could compromise safety.

Maintenance of aluminum railings is relatively straightforward but crucial for preserving their appearance and functionality. Regular inspections should be conducted to check for signs of wear, corrosion, or damage, especially in coastal areas where salt can accelerate degradation. Cleaning the railings periodically with mild soap and water will help remove dirt and grime, preventing buildup that can lead to corrosion. Additionally, applying a protective coating can enhance the durability of the aluminum, ensuring that it remains visually appealing and structurally sound over time.

This chart represents the average installation time and maintenance frequency required for various types of aluminum railing systems. The data reflects common practices in the industry.