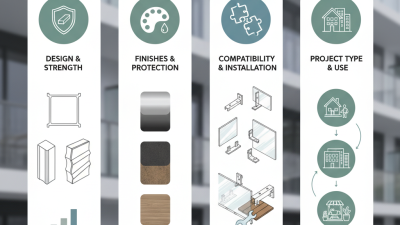

Choosing the right Aluminum Ceiling Extrusion is crucial for your project. The right choice not only impacts aesthetics but also performance. Aluminum ceilings offer durability and versatility. However, with so many options available, making a selection can be challenging.

You need to consider factors such as design, functionality, and budget. Each project has unique requirements. An unsuitable extrusion might lead to structural issues or visual inconsistencies. Reflecting on your specific needs will guide you toward a more informed decision.

Understanding the characteristics of different Aluminum Ceiling Extrusions can make a difference. Explore textures, finishes, and installation methods that best suit your space. Sometimes, the most beautiful designs are not the most practical. So, evaluating both style and function is essential for a successful outcome.

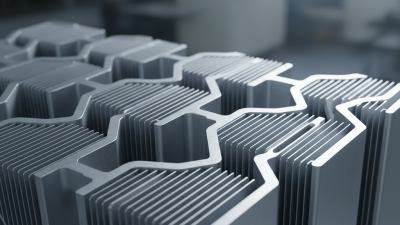

Aluminum ceiling extrusions are versatile and functional. They come in various shapes and sizes, making them perfect for different applications. For example, they can create a sleek modern look in offices or homes. They also help with light management, allowing for creative lighting designs. Their durability ensures that they withstand wear and tear over time.

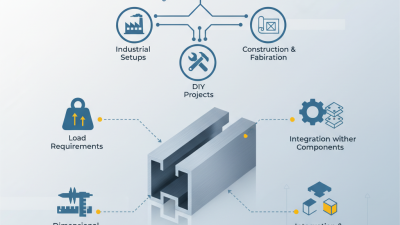

When choosing the right extrusion, consider the project requirements. Think about weight limits and design aesthetics. Using the wrong extrusion can lead to project delays or increased costs. Reflect on the long-term implications of your choice. A well-chosen extrusion can enhance both functionality and appearance. Conversely, a poor choice may lead to disappointment. Always visualize how your selected extrusion complements the overall design.

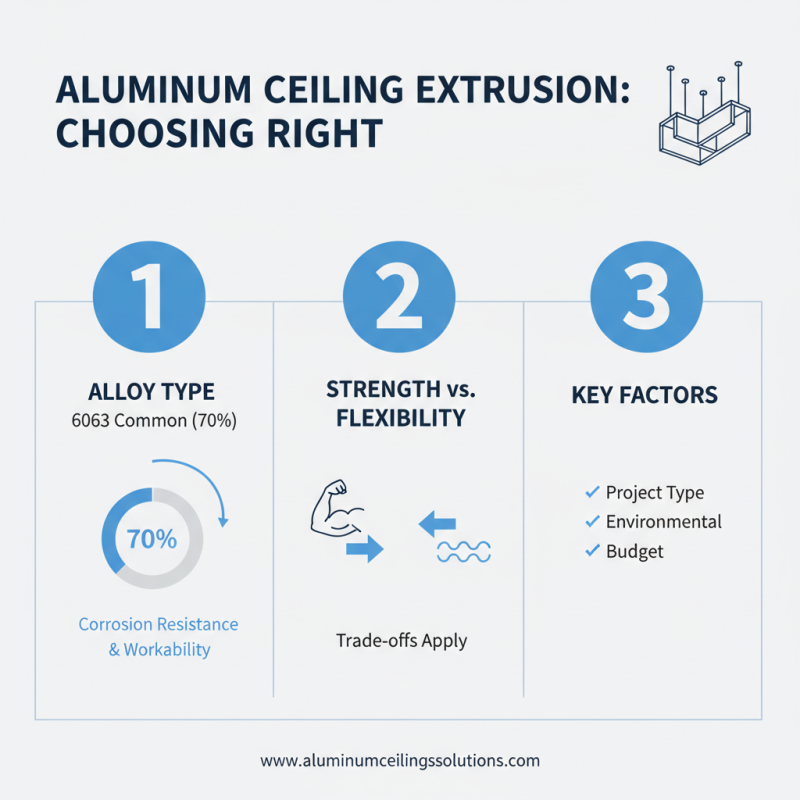

Choosing the right aluminum ceiling extrusion for your project involves careful consideration of several key factors. One significant aspect is the alloy type. Alloys like 6063 are common due to their excellent corrosion resistance and workability. According to industry reports, nearly 70% of aluminum extrusions used in ceilings are of this alloy. However, one must also consider the trade-offs in strength versus flexibility.

Another critical factor is the extrusion quality. Look for products that comply with the standards set by organizations like the Aluminum Association. Quality assurance can often separate top-tier products from mediocre ones. Recent studies indicate that improper selection can lead to a 15% increase in maintenance costs down the line. Visual aesthetics are important as well, but should not overshadow structural integrity.

Installation complexity plays a role too. Some extrusions require specialized tools and experience, which can inflate a project's budget. Recent surveys show that 30% of contractors feel unprepared for installing certain designs. It is essential to weigh convenience against potential installation challenges, as both will impact project timelines and costs. Striking the right balance is crucial for a successful outcome.

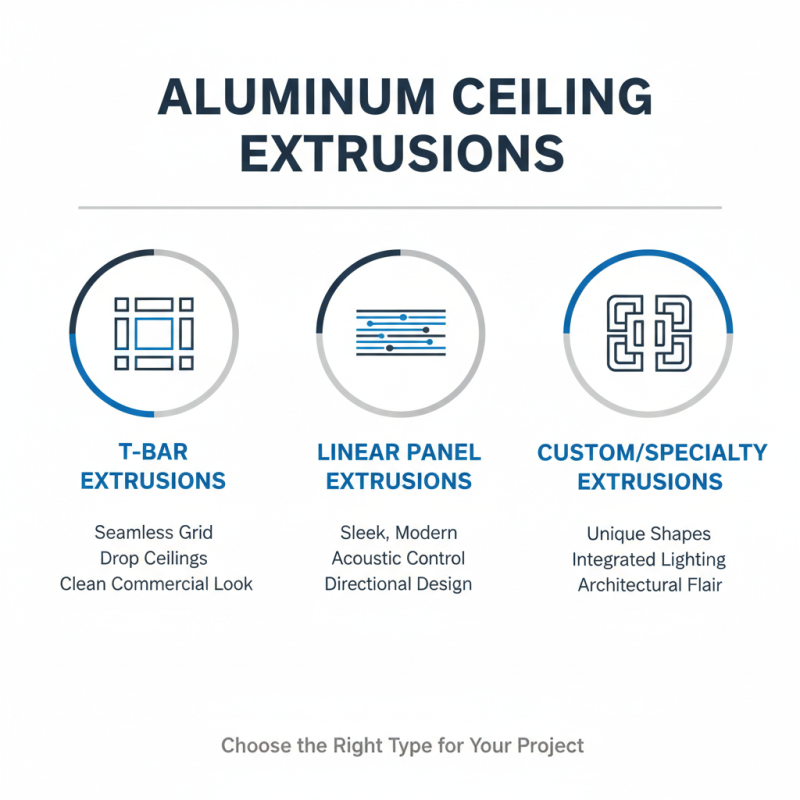

When selecting aluminum ceiling extrusions, consider the various types available. Each type has unique benefits that cater to different project needs. For instance, T-bar extrusions provide a seamless grid appearance. They are ideal for drop ceilings. This type creates a clean look in commercial spaces.

Another popular option is L-shaped extrusions, which offer flexibility in design. These can strengthen corner joints effectively. They also add aesthetic appeal to your ceiling. Notably, U-shaped extrusions can conceal wiring and ductwork. This keeps views uncluttered. Many choose this style for modern interiors.

It’s essential to weigh the advantages of each type against your project's requirements. Consider factors like the ceiling's height and the intended use of space. You may find that one style does not fit all scenarios. Sometimes, custom solutions are necessary for your unique vision. Reflecting on your choices will ensure a more satisfying outcome.

When choosing aluminum ceiling extrusions, understanding quality standards is vital. Various certifications indicate reliability. Look for extrusions that comply with recognized industry standards. This ensures they meet performance and safety benchmarks.

Tips: Check for certifications like ISO and ASTM. These can validate the quality of the extrusions. Don’t overlook local regulations; compliance can vary.

Quality assessment involves inspecting materials used. High-grade aluminum is lightweight but durable. Look for options with a good finish. This not only enhances aesthetics but improves resistance to environmental factors.

Tips: Inspect samples for imperfections. Scratches or dents may indicate poor handling or storage, impacting longevity. Reflect on individual project needs rather than opting for generic solutions. It's easy to overlook specific requirements in pursuit of cost-effectiveness.

| Quality Standard | Description | Certification Body | Applicable Regions |

|---|---|---|---|

| ISO 9001 | Quality management systems requirements | International Organization for Standardization | Globally recognized |

| ASTM B221 | Standard specification for aluminum extruded bars, rods, shapes, and tubes | ASTM International | USA, Canada |

| EN 12020 | Aluminum and aluminum alloys - Extruded precision profiles | European Committee for Standardization | European Union |

| AAMA 2605 | Voluntary specification for high-performance organic coatings on aluminum extrusions | American Architectural Manufacturers Association | USA |

| ISO 14001 | Environmental management systems | International Organization for Standardization | Globally recognized |

When budgeting for an aluminum ceiling project, consider various factors affecting costs. The average pricing for aluminum ceiling extrusions can range from $5 to $15 per linear foot, depending on the complexity and design. This variance often challenges project managers and designers in achieving an attractive visual while maintaining a strict budget.

Labor costs can significantly impact your overall expenses. Reports suggest that labor might account for up to 50% of total installation costs. While aluminum is lighter than other materials, skilled labor is essential for proper installation. Inadequate installation could lead to future repairs, causing even more financial strain.

Additionally, don't overlook potential hidden costs. Maintenance and insurance should be factored into your budget. Some installers recommend budgeting an extra 10-20% for unforeseen complications. The fluctuation of aluminum prices can also affect your project. Tracking market trends is paramount. Remember, a well-planned budget can save you stress and money in the end.