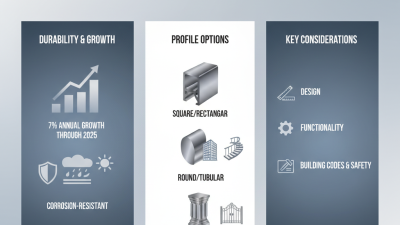

When embarking on a project that requires an Aluminum Square Plate, careful selection is crucial. The right choice can dramatically impact the durability and performance of your project. According to a report by the Aluminum Association, the demand for aluminum products, including square plates, has risen by 12% over the last five years. This underscores the importance of choosing high-quality materials to meet industry standards.

Aluminum Square Plates come in various grades, sizes, and finishes. Understanding these options can help determine the best fit for specific applications. Additionally, the market is shifting towards eco-friendly materials. Nearly 30% of aluminum is recycled, showcasing the industry's commitment to sustainability. You may face challenges in balancing cost and quality. This aspect requires careful consideration to avoid potential pitfalls in your project.

In summary, selecting the right Aluminum Square Plate demands informed decision-making. Analyzing your project's specific needs is key, and consulting expert resources can provide valuable insights. This process can be daunting but ultimately leads to more successful project outcomes.

When choosing aluminum square plates, understanding their basics is crucial. Aluminum plates come in various grades and thicknesses. The most common grade is 6061, known for its strength and corrosion resistance. Industry reports suggest that the demand for aluminum plates has increased by over 15% in the last five years. This trend is driven by their applications in construction and manufacturing.

Thickness is another key aspect to consider. Standard thicknesses range from 1/8 inch to 1 inch. Choosing the wrong thickness can lead to structural issues or excess weight. Consider your project's specific needs. For instance, a lightweight design may require thinner plates.

**Tip**: Always check the specifications. Ensure the plate meets your project's weight and load requirements.

Another factor is the surface treatment. Anodized finishes can enhance durability. However, not all projects may require this. Understanding your environment is important. If the aluminum will face harsh conditions, treat it accordingly.

**Tip**: Take a moment to reflect on your project’s long-term needs. This helps avoid costly mistakes later on.

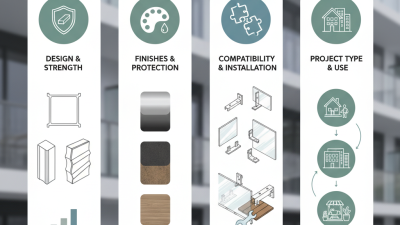

Choosing the right aluminum square plate requires careful consideration of several factors. One important aspect is the thickness of the plate. Thicker plates offer more strength and durability but can be heavier and more expensive. Identify the load requirements of your project. If you need a lightweight option, a thinner plate might suffice. For structural applications, weight should not be the only focus.

Another factor to think about is the intended use of the plate. Will it be exposed to weather conditions? If so, consider the corrosion resistance of the aluminum alloy. Some alloys handle moisture better than others. If the project involves fabrication, think about how easily the plate can be cut or shaped. Not all plates are suited for intricate designs and modifications.

Moreover, the finish of the aluminum plate plays a vital role. A brushed finish can enhance appearance but could make the surface more prone to scratches. A smooth finish may be easier to clean but might not offer the desired grip for certain applications. Reflect on these details thoroughly. Mistakes in choosing the right plate can lead to unforeseen issues in your project.

Aluminum square plates are versatile materials used across many industries. In construction, they serve as durable bases for structures. Their lightweight nature makes them easy to handle, reducing overall project weight. Many builders prefer aluminum for its corrosion resistance. However, the choice of thickness can be an issue. Thicker plates may be required, leading to increased costs.

In the automotive sector, aluminum square plates support engine components. They can withstand high temperatures while maintaining structural integrity. Yet, it's crucial to ensure the right alloy is chosen. A wrong selection can impact performance significantly. In packaging, aluminum plates enable effective barrier properties. They protect contents from moisture and light. Although, achieving a perfect seal can sometimes be challenging. Small imperfections can lead to spoilage.

The aerospace industry demands precision materials. Aluminum plates are essential in aircraft design, offering strength without excessive weight. However, drilling and machining must be accurate. Misalignment can result in safety hazards. Innovating through testing is vital. Each application requires a careful evaluation of the plate's specifications to meet strict standards.

| Industry | Common Applications | Plate Thickness (mm) | Plate Size (mm) |

|---|---|---|---|

| Aerospace | Aircraft components, structural frames | 2 - 10 | 1000 x 1000 |

| Automotive | Body panels, engine parts | 1.5 - 8 | 500 x 500 |

| Construction | Building facades, roofing elements | 3 - 12 | 2000 x 1000 |

| Electronics | Heat sinks, enclosures | 1 - 6 | 300 x 300 |

| Marine | Boat hulls, deck components | 4 - 10 | 1500 x 500 |

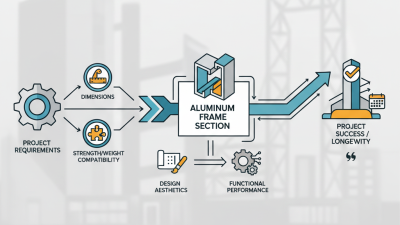

When selecting an aluminum square plate, consider different grades and specifications. Aluminum alloys vary in strength, weight, and corrosion resistance. The most common grades are 6061 and 5052. Each grade serves specific purposes.

For example, 6061 is strong and versatile, often used in structural applications. It is well-suited for machining and welding. On the other hand, 5052 boasts excellent corrosion resistance. This makes it ideal for marine environments. Choosing between these grades can be challenging.

Think about your project's specific needs. Will it face extreme conditions? How important is weight? Reflect on these questions. Sometimes, the perfect choice isn't clear. You might need several tests before finding the ideal plate. Keep an open mind during your selection process.

When sourcing aluminum square plates, consider key factors. The thickness and dimensions matter greatly. Measure your project’s requirements carefully. An incorrect size can lead to a waste of materials.

Quality should be a priority. Look for suppliers that provide detailed specifications. Certifications can indicate if the aluminum meets industry standards. Testing the plates for durability might also be wise. A small scratch can affect how it performs later.

Start by visiting local suppliers. Sometimes, inspecting the material in person can reveal issues. Also, ask questions. A knowledgeable supplier can guide you. You may find differences in quality even among similar-looking plates. Pay attention to these details. They can save you from future troubles.