Aluminium Angle Extrusion Slats offer versatile solutions for various projects. These slats are lightweight yet durable. They can be used in construction, furniture, and craft applications. Understanding how to use them effectively can enhance your project’s overall quality.

Choosing the right Aluminium Angle Extrusion Slats is crucial. Measure your space accurately before deciding. It’s easy to miscalculate dimensions. This can lead to wasted materials and time. Ensure that the slats fit your specific needs. Adaptability is key when working with them.

Also, consider the finishing techniques. Adding a coat of paint or using protective coatings can prevent rust. Yet, some may overlook this step. It’s important to reflect on these choices. Effective use of Aluminium Angle Extrusion Slats involves thoughtful planning and execution.

Aluminium angle extrusion slats are widely used in various applications, including construction and automotive industries. Their strength and lightweight properties make them versatile. However, it's essential to maximize their potential for effective use.

One tip is to consider the correct dimensions. The ideal width and thickness depend on the project demands. Selecting the wrong size may result in weak structures. An industry study indicated that improper sizing can lead to a 30% reduction in strength. Keep in mind the load the slats will support.

Another point to ponder is the finishing process. Raw aluminium can be prone to corrosion and wear. Anodizing or powder coating can double the lifespan of the material. However, some may overlook this step, thinking it’s unnecessary. In reality, exposure to moisture can deteriorate the slats quickly.

When joining slats, ensure a proper fit. Misalignment not only compromises structural integrity, but it can lead to additional costs. According to reports, an estimated 25% of construction delays stem from poor assembly practices. Reflections on past projects could prevent future mistakes and improve efficiency.

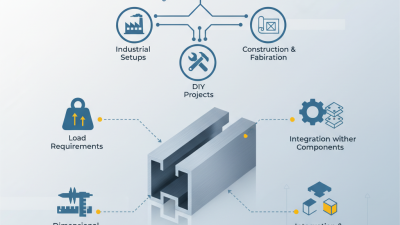

Aluminium angle extrusion is a versatile material widely used in various applications. Its strength and lightweight nature make it ideal for construction, manufacturing, and DIY projects. The L-shaped profile provides stability and support in frameworks, making it a popular choice among builders and designers.

When using aluminium angle extrusion slats, consider their placement carefully. Misalignment can weaken the structure. Use a level to ensure precision. This small step prevents larger issues later on. Proper tools also make a significant difference. Invest in cutting tools that ensure clean edges. Jagged cuts can compromise the integrity of your project.

Be mindful of joint connections. They need to be secure yet adjustable if necessary. A loose joint might lead to functional failures over time. Lastly, don't overlook aesthetics. Clean, polished angles can elevate the overall look of your project. Ignoring this could result in a less appealing finish.

| Tip Number | Tips | Benefits | Applications |

|---|---|---|---|

| 1 | Choose the Right Profile | Maximize structural integrity | Framing and support structures |

| 2 | Optimize Cutting Techniques | Reduce waste and improve efficiency | Custom fabrication projects |

| 3 | Utilize Proper Fastening Methods | Enhance stability and durability | Assembly of modular designs |

| 4 | Consider Surface Treatments | Improve corrosion resistance | Outdoor applications |

| 5 | Plan Layout and Design | Enhance functionality and aesthetics | Architectural installations |

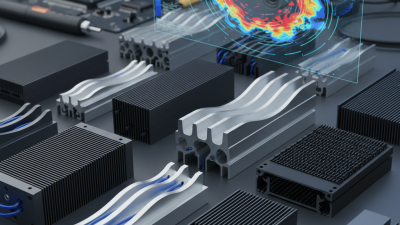

When considering the use of aluminium angle extrusion slats, optimal design and dimensions are crucial. Various projects require specific specifications to maximize efficiency and performance. Industry reports indicate that the strength-to-weight ratio of aluminium makes it ideal for constructing lightweight yet robust frameworks. The selection of dimensions, such as width and thickness, significantly impacts the rigidity and load capacity of the slats.

Tip 1: Assess your project’s needs upfront. A smaller width might suffice for light-duty applications, but larger slats are necessary for heavy loads.

Furthermore, the design should account for environmental factors. Exposure to moisture can lead to corrosion. A thicker extrusion may provide better protection in harsh conditions. According to industry analyses, proper surface treatment can enhance longevity and resistance to wear.

Tip 2: Always prioritize surface treatment. It can significantly extend the lifespan of your slats, making them more effective in the long run.

Finally, keep in mind potential miscalculations in your dimensions. Misjudging can lead to structural failures. Regular assessments and adjustments to design schemes can prevent costly mistakes. Remember, achieving optimal efficiency often requires trial and error.

This chart illustrates the performance metrics for aluminium angle extrusion slats, highlighting important factors such as dimensions, weight capacity, cost, durability rating, and flexibility. These parameters help in determining the effectiveness of extrusion slats in various projects.

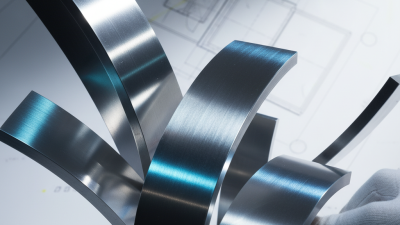

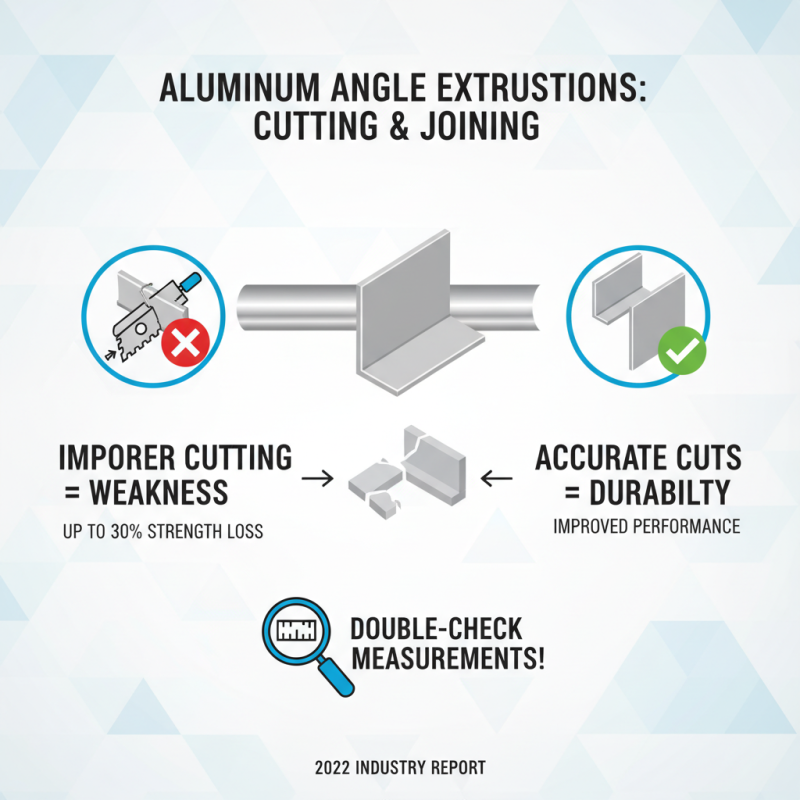

Aluminium angle extrusions are widely used in various industries. Effective cutting and joining impact the durability and performance of these materials. According to a 2022 industry report, improper cutting can weaken the structural integrity by up to 30%. Accurate measurements are critical. Always double-check before making cuts.

Using a high-speed saw is recommended for clean cuts. Blade selection matters—it directly affects the finish. A blade with finer teeth will minimize burrs and ensure smoother edges. This also aids in achieving tighter joints. Many professionals overlook the need for proper clamping. Loose pieces can shift, leading to misalignment. This inconsistency can cause unnecessary rework and increased costs.

Joining methods vary based on the application. Welding offers a strong bond but requires skill and experience. Adhesives can be viable alternatives for certain projects, often providing quicker assembly. However, their strength can vary by formulation. Proper surface prep is essential for adhesives. Some users neglect this step, resulting in bond failure. Testing different methods on scrap pieces can yield valuable insights.

When it comes to the strength and durability of aluminium slats, several factors play a crucial role. The alloy composition is vital; different blends can affect structural integrity. Thicker slats typically exhibit more strength, yet they can be heavier and harder to install. Consider the environment too; moisture and temperature fluctuations can impact longevity. Applying a protective coating may help combat corrosion, providing a longer lifespan.

To use aluminium angle extrusion slats effectively, pay attention to installation. Ensure proper alignment during setup to prevent stress points. This reduces the chances of warping or bending over time. Choosing the right fasteners is essential. Use corrosion-resistant ones for outdoor applications. It’s a common mistake to overlook the importance of sealing joints properly—this can lead to moisture intrusion and, eventually, damage.

Maintenance is another key aspect. Regularly inspect the slats for signs of wear or damage. Addressing small issues immediately can prolong the slat's life. Remember, the installation surface matters. A solid foundation ensures stability. Skipping this step can lead to problems later. Aluminium slats can be strong, but they require attention to detail. The effort will pay off in durability and overall performance.

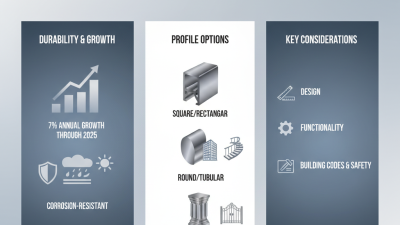

Aluminium Angle Extrusion Slats are versatile components widely used in various industries due to their strength, light weight, and resistance to corrosion. Understanding the benefits and applications of these slats is essential for maximizing their potential in any project. By optimizing the design and dimensions tailored to specific applications, one can enhance structural integrity while achieving functional goals.

Effective cutting and joining techniques are critical in utilizing Aluminium Angle Extrusion Slats, as they can influence the final assembly's durability. Moreover, recognizing the factors that contribute to the strength and longevity of these slats ensures they perform well over time. Regular maintenance practices also play a pivotal role in prolonging their lifespan, making it essential for users to incorporate these tips for optimal usage.