Industrial Aluminium Ceiling Extrusions are crucial in modern architecture. These specialized components offer versatility and functionality in various building projects. Their lightweight nature and impressive strength make them a popular choice for ceiling design.

In commercial and industrial settings, these extrusions are often used to create elegant and durable ceilings. They can support lighting fixtures and HVAC systems efficiently. Many designers appreciate how these extrusions simplify installation and reduce labor costs.

While the benefits are significant, the market does face challenges. Some manufacturers may not adhere to high-quality standards. This raises concerns about durability and long-term performance. Reflecting on these issues can lead to improvements in product quality. Embracing the advantages of Industrial Aluminium Ceiling Extrusions while addressing these flaws is essential for future development in this field.

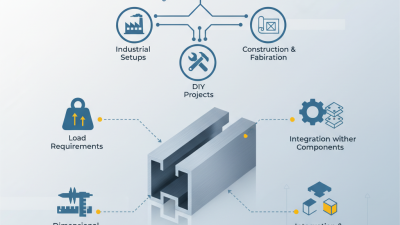

Industrial aluminium ceiling extrusions are specialized components used in modern architecture and design. These extrusions are lightweight yet sturdy, making them ideal for ceiling applications. They provide structural support for ceiling panels while maintaining an aesthetic appeal.

The use of aluminium in ceiling systems is backed by data from industry reports. The global market for ceiling systems is projected to reach $17.5 billion by 2025, with aluminium products witnessing significant growth. A study indicated that the lightweight nature of aluminium can reduce overall building weight by up to 30%. However, the eco-friendliness of aluminium poses challenges. While it’s recyclable, production involves high energy consumption, leading to a debate over its full sustainability.

Aluminium ceiling extrusions come in various shapes and sizes, catering to unique design needs. These can be used in commercial spaces, like offices and retail stores, for enhanced aesthetics. However, installation can be tricky, requiring skilled labor. A poorly installed ceiling can lead to sagging, which compromises safety and design integrity. Despite these challenges, the flexibility and durability of aluminium make it a preferred choice for innovative ceiling solutions.

| Dimension | Description | Application |

|---|---|---|

| Length | Typically available in lengths from 2 to 6 meters. | Used in the construction of ceiling systems. |

| Width | Widths can vary from 100 mm to 300 mm. | Applied in creating different designs of ceiling paneling. |

| Thickness | Commonly 0.5 mm to 2 mm depending on design strength. | Important for load-bearing ceilings and durability. |

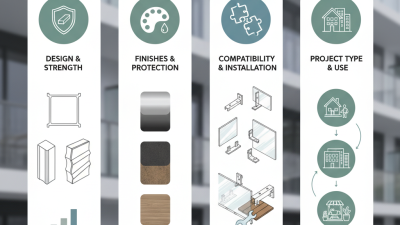

| Finish | Available in powder-coated, anodized, or natural finishes. | Enhances aesthetic appeal and corrosion resistance. |

| Weight | Density ranges typically from 2.5 to 3.0 g/cm³. | Lightweight properties facilitate easy installation. |

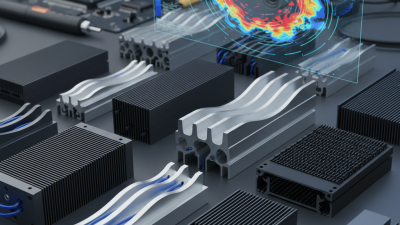

| Thermal Conductivity | Good thermal conductivity around 205 W/m·K. | Useful for thermal management in buildings. |

Aluminium extrusions are popular for industrial ceilings due to their lightweight nature and durability. They offer excellent resistance to corrosion, making them ideal for various environments. These characteristics contribute to their longevity. The ability to shape aluminium into complex profiles provides flexibility for design. This adaptability is useful in modern architecture.

Beyond aesthetics, aluminium extrusions improve energy efficiency. They can support insulation materials effectively. This results in reduced energy costs over time. Additionally, aluminium’s recyclable properties appeal to eco-conscious businesses. However, the production process can be energy-intensive. Balancing sustainability with production efficiency is a challenge.

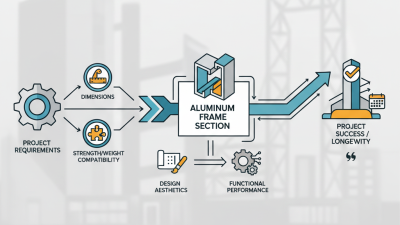

Moreover, installation can sometimes be tricky. Misalignment can lead to structural weaknesses. Proper planning and precise measurements are essential. Yet, once installed correctly, these ceilings offer an innovative look. They create a clean, contemporary space that is now sought after in commercial buildings. Understanding these nuances is crucial for manufacturers and builders alike.

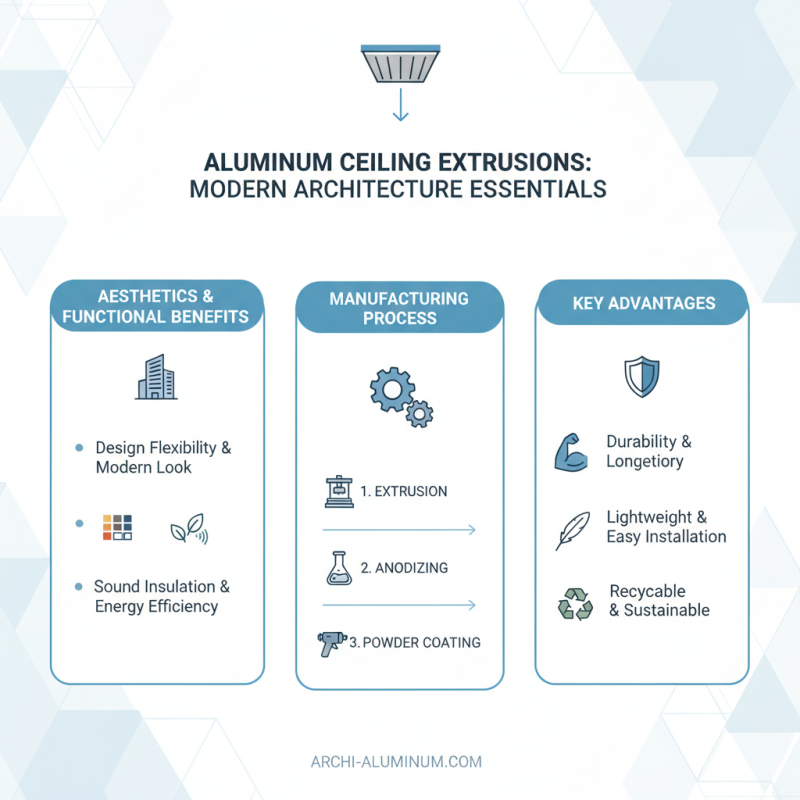

Aluminium ceiling extrusions are integral in modern architecture. They not only enhance aesthetics but also provide functional benefits like sound insulation and energy efficiency. The manufacturing of these extrusions involves several key processes, including extrusion, anodizing, and powder coating.

The extrusion process begins by heating aluminium billets. The heated aluminium is then pushed through a die to create desired profiles. Reports indicate that this method can produce complex shapes, with tolerances as tight as 0.1 mm. After extrusion, a common treatment is anodizing. This process enhances corrosion resistance and allows for a variety of color finishes. Research shows that anodized surfaces can extend the life of the product significantly.

After anodizing, powder coating is often employed. This gives a durable finish that is resistant to chipping and fading. However, achieving perfect adhesion can sometimes be challenging. Variability in surface preparation may lead to peeling. An important aspect to consider is the environmental impact of these processes. While aluminium is recyclable, the energy consumption during manufacturing remains a concern for sustainability. Balancing efficiency and eco-friendliness is essential for future developments in the industry.

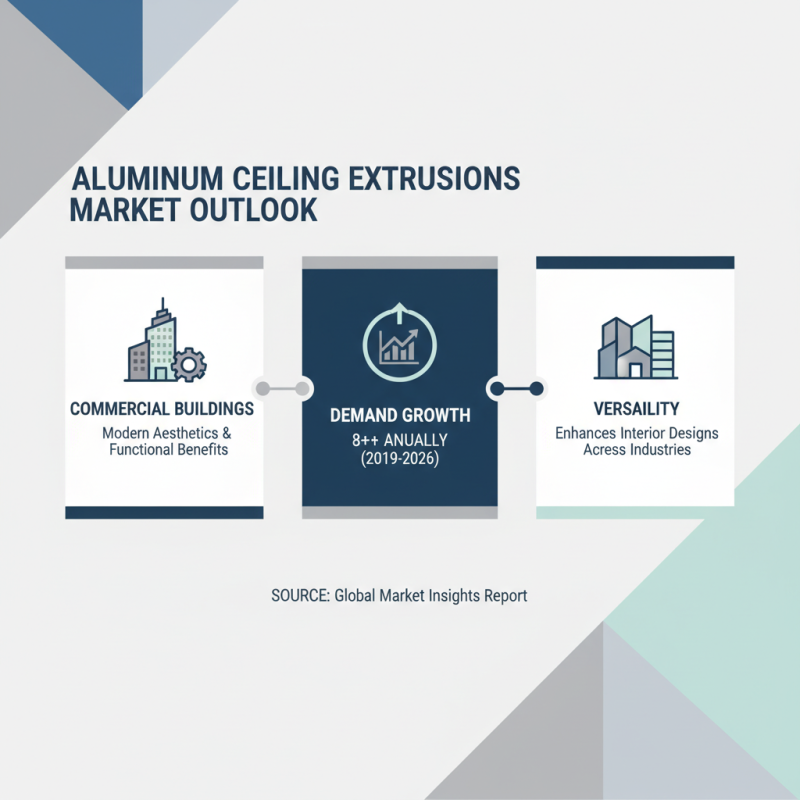

Aluminium ceiling extrusions have found extensive applications across various industries. In commercial buildings, these extrusions offer a modern aesthetic while providing functional benefits. According to a recent report from the Global Market Insights, the demand for aluminium ceiling systems is expected to grow by over 8% annually until 2026. This surge highlights the versatility of aluminium in enhancing interior designs.

In the healthcare sector, aluminium ceiling extrusions play a crucial role in creating sterile environments. They are easy to clean and resistant to corrosion. Hospitals and clinics favor these materials for their durability and hygienic properties. Additionally, manufacturers are now investing in more sustainable aluminium options. However, the industry still faces challenges related to recycling and end-of-life management for these materials.

The hospitality industry uses aluminium ceiling extrusions to create eye-catching designs. They allow for flexibility in lighting and can hold various ceiling fixtures. Data suggests that 30% of hotel renovations incorporate aluminium features. Yet, there’s a missed opportunity to innovate further. Many designs still rely on conventional shapes, leaving room for more creative approaches. This stagnation may hinder the potential of aluminium in this sector.

The future of aluminium ceiling extrusion technology is promising yet complex. Innovations in materials and production methods are transforming the industry. Designers are now focusing on sustainability. Advanced extrusion techniques are reducing waste. This not only makes the process greener but also more cost-effective.

Emerging trends include the integration of smart technologies. Think of ceilings that can change color or lighting. This adds functionality in modern spaces. However, many manufacturers struggle to keep up with these advancements. Adapting to new technology requires investment and expertise. Some face challenges in sourcing sustainable raw materials.

The diversity in design options is notable, yet it presents its own issues. Achieving both aesthetic appeal and functionality is tough. Future designs may lean towards minimalism, but they must also cater to varying consumer needs. Balancing innovation, cost, and sustainability is a delicate dance for the industry.