In the world of construction and fabrication, the choice of materials plays a critical role in the success of any project. Among the myriad of options available, one product that stands out for its versatility and ease of use is the Aluminium T Slot Profile. This innovative structural framework is designed to offer robust support while allowing for a high degree of customization, making it ideal for a variety of applications, from industrial setups to DIY projects.

Selecting the best Aluminium T Slot Profile for your specific needs can seem daunting, given the variety of sizes, shapes, and finishes available on the market. Properly understanding the parameters and characteristics of these profiles is essential for ensuring that your projects not only meet their functional requirements but also achieve aesthetic appeal. In this article, we will explore key considerations for choosing the right Aluminium T Slot Profile, including load requirements, dimensional accuracy, and integration with other components, enabling you to make informed decisions for your next project.

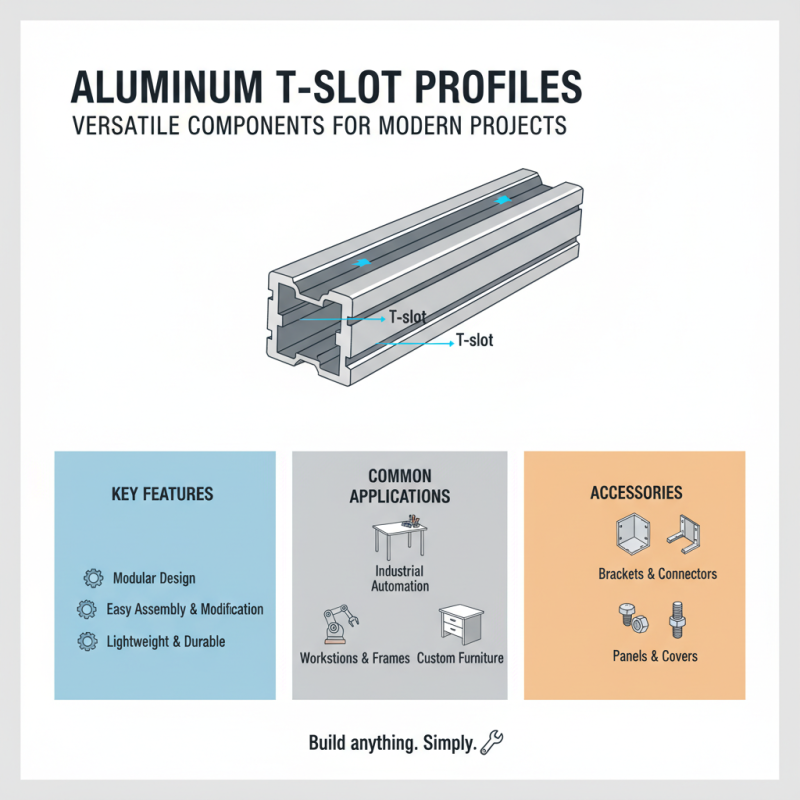

Aluminium T slot profiles are versatile components commonly used in various industries, ranging from automation to custom furniture design. Their unique design includes a grooved profile that allows for easy assembly and modification of structures. These profiles can be combined with a wide range of accessories, such as brackets and connectors, enabling users to create customized solutions tailored to their specific needs. Understanding the applications of aluminium T slot profiles can help you make informed decisions for your projects, whether you're building a simple frame or an intricate workstation.

Tips: When selecting T slot profiles, consider the load requirements of your project. Assess the weight that the structure will need to support and choose a profile with a cross-section that provides sufficient strength. Additionally, think about the level of flexibility you desire; profiles with wider slots allow for more configuration options as your project evolves over time.

Another critical aspect to consider is the ease of assembly. Look for profiles that provide simple installation processes, particularly if you are working with limited experience or tools. Opting for profiles that come with pre-machined holes may save you time and improve the overall structural integrity of your project. Knowing how T slot profiles integrate with various components can also facilitate a smoother design process and enhance the functionality of your end product.

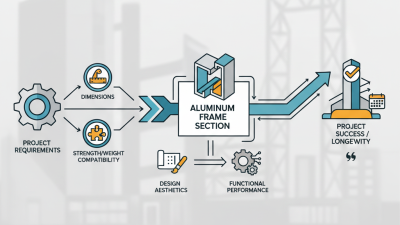

When selecting the best aluminium T slot profiles for your projects, it is crucial to consider several key factors to ensure optimal performance and compatibility with your specific needs. First and foremost, you should evaluate the dimensions of the profiles. The size and geometry of the T slots will significantly impact the structural integrity and versatility of your assembly. Profiles come in various widths, heights, and slot configurations; selecting the right dimension ensures that you can easily integrate accessories such as fasteners, brackets, and connectors.

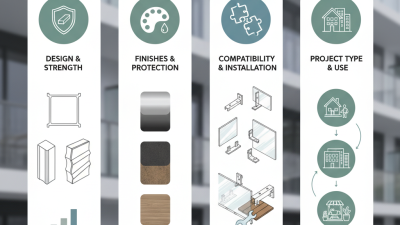

Another important factor to take into account is the material properties of the aluminium used in the profiles. The hardness, weight, and corrosion resistance of the aluminium alloy can affect not only the durability of the final structure but also its suitability for various environments. For instance, certain profiles may be better suited for outdoor applications or humid environments due to their anodized finishes. Furthermore, consider how the profiles will be used in terms of load-bearing capacities; ensuring that the chosen profile can adequately support the intended weight is essential for safety and functionality.

Lastly, ease of assembly and design flexibility are vital components that cannot be overlooked. Opt for aluminium T slot profiles that allow for straightforward assembly processes, as this can save time and reduce construction costs. Profiles that offer multiple joining options can provide greater design flexibility, enabling you to create intricate structures tailored to your project's requirements. Evaluating these factors will lead you to make an informed decision that aligns with the objectives of your project.

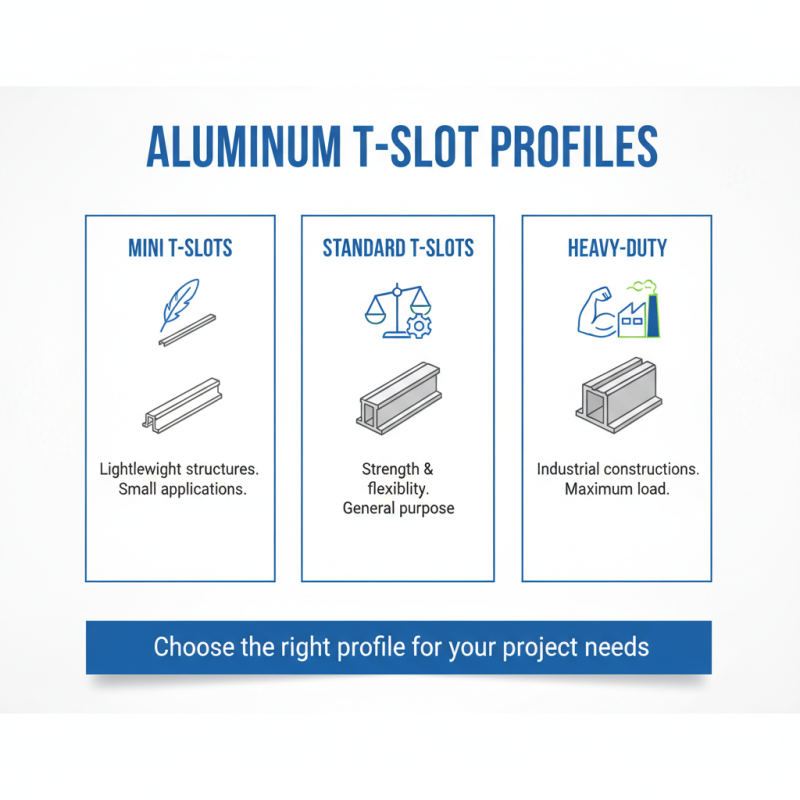

When selecting the best aluminium T slot profile for your projects, it's essential to understand the various types available in the market. Each profile is designed for specific applications, providing distinct advantages based on your project needs. Common types include mini T slots, standard T slots, and heavy-duty T slots. Mini T slots are great for lightweight structures and smaller applications, while standard T slots offer a balance of strength and flexibility for many general purposes. Heavy-duty T slots are ideal for robust, industrial-scale constructions that require maximum load-bearing capabilities.

Tips for choosing the right profile include assessing the load requirements of your project and considering the environmental factors such as moisture and temperature that may impact the aluminium. Additionally, think about the ease of assembly and customization. Profiles with multiple attachment points can facilitate a more versatile design, allowing for adjustments and expansions without significant structural changes.

Another important consideration is the surface finish of the T slot profiles. Anodized finishes can provide additional resistance to corrosion and wear, while painted options allow for aesthetic customization. Evaluate how the surface finish may contribute to the longevity and appearance of your project, ensuring that your selection aligns with both functional and visual requirements.

When selecting the right accessories for aluminium T slot profiles, it's essential to consider the compatibility and functionality of each component. Aluminium T slot profiles are versatile and widely used in various industries, from manufacturing to automation. Reports indicate that the global market for aluminium extrusions is projected to reach $126.5 billion by 2028, underscoring the importance of choosing high-quality accessories that enhance the efficiency and durability of your projects.

Key accessories to consider include connectors, brackets, and fasteners, all of which play a crucial role in assembly and stability. According to a recent industry analysis, the proper selection of these accessories can improve the strength of a framework by up to 30%. Additionally, the right fastening solutions, such as T-nuts and bolts, ensure that the profiles remain secure and can withstand varying loads and operational demands.

Furthermore, integrating additional components like sliding doors, shelves, and casters can significantly increase the functionality of your aluminium structures. Statistics show that workspaces utilizing modular systems with T slot profiles can increase productivity by as much as 15%. By carefully selecting the right accessories, you can create customizable and adaptable solutions that not only meet your project requirements but also future-proof your investment in aluminium T slot technology.

| Profile Type | Dimension (mm) | Weight (kg/m) | Applications | Recommended Accessories |

|---|---|---|---|---|

| 40 x 40 | 40 x 40 | 1.5 | Machine frames, Workstations | Corner Brackets, Bolts |

| 30 x 60 | 30 x 60 | 1.2 | Conveyor Frames, Guards | Mounting Plates, End Caps |

| 45 x 90 | 45 x 90 | 1.8 | Assembly Structures, Racks | Joining Plates, T-nuts |

| 20 x 20 | 20 x 20 | 0.6 | Lightweight Fixtures, Railing | Angle Brackets, Spacer Blocks |

| 80 x 40 | 80 x 40 | 2.5 | Heavy Duty Frames, Stands | Cross Connectors, Fasteners |

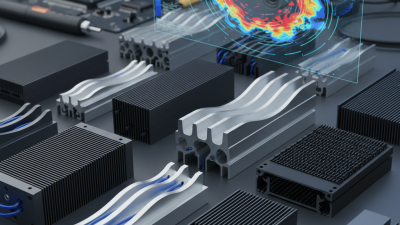

When selecting and assembling aluminium T slot profiles, it is essential to incorporate best practices to maximize efficiency and effectiveness in your projects. One key aspect is understanding the weight-bearing capacity of your chosen profiles. According to a report by the Aluminium Federation, well-designed T slot profiles can support loads up to 2000 kg per square meter, which makes them suitable for a range of applications from industrial structures to modular workstations. It’s crucial to match the profile selection with the intended load, ensuring the stability and longevity of the assembly.

Another best practice is ensuring precise measurements and alignments during the assembly process. A study published in the Journal of Structural Engineering indicates that misalignment can decrease the load-bearing capacity significantly, potentially leading to structural failure. Utilizing tools such as laser measuring devices or digital angle finders can enhance accuracy. Furthermore, employing corner brackets and connectors designed specifically for T slot profiles can improve rigidity and safety of the assembly. Following these practices not only promotes durability but also facilitates easier future modifications or expansions, accommodating evolving project needs.