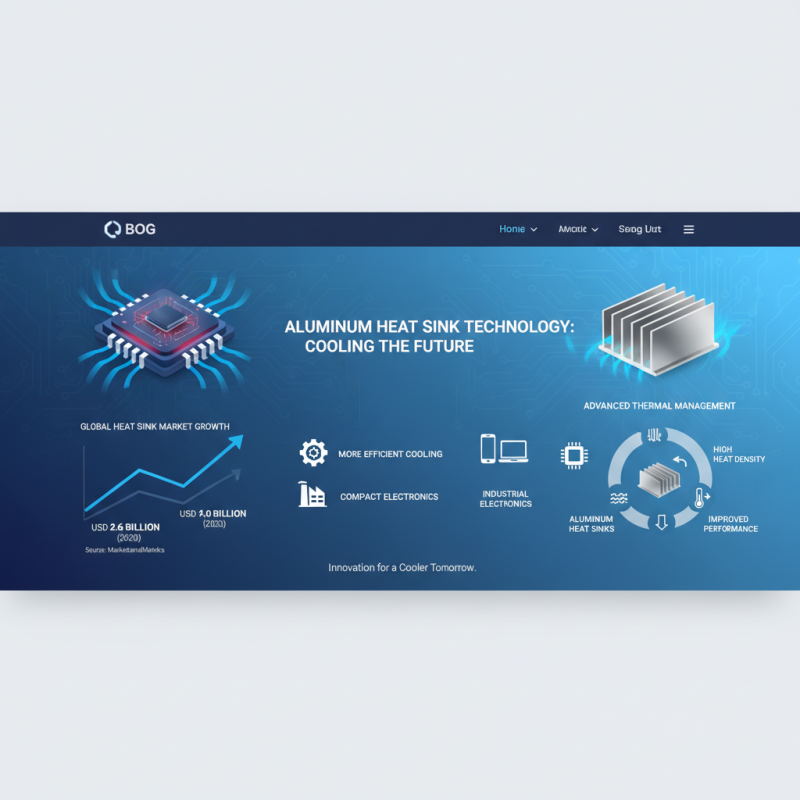

In the fast-evolving realm of electronics and thermal management, the importance of effective cooling solutions cannot be overstated. As devices become more compact and powerful, the demand for efficient thermal dissipation has surged, making the choice of materials and design crucial. According to a report by Smith Research, the market for Aluminium Heat Sink Profiles is projected to reach $2.5 billion by 2025, driven by the rising applications in sectors such as automotive, consumer electronics, and renewable energy technologies. These profiles are particularly sought after for their excellent thermal conductivity, lightweight nature, and versatility in design.

Industry expert Dr. Jane Nelson, a leading figure in thermal management solutions, emphasizes the critical role of Aluminium Heat Sink Profiles, stating, "The right heat sink profile not only enhances performance but also prolongs the lifecycle of electronic components." This highlights the necessity for manufacturers to stay ahead by optimizing their cooling solutions. As we explore the top aluminium heat sink profiles in 2025, we aim to shed light on the latest innovations, design trends, and best practices, ensuring that power electronics maintain optimal performance and reliability in an increasingly demanding technological landscape.

In 2025, the pursuit of optimal cooling solutions continues to intensify, especially in high-performance applications where efficient thermal management is critical. Aluminium heat sink profiles stand out due to their exceptional thermal conductivity, lightweight nature, and versatility in design. One of the key characteristics of these profiles is their ability to dissipate heat effectively, ensuring that electronic components maintain optimal operating temperatures, thereby enhancing their longevity and reliability.

Another significant characteristic of aluminium heat sinks is their customizable designs, which can be tailored to fit various applications. From intricate shapes that maximize surface area to fin configurations that improve airflow, these profiles can be engineered to meet specific needs. Additionally, the corrosion resistance of aluminium allows heat sinks to perform reliably in diverse environments, making them suitable for both indoor and outdoor applications. These features, combined with their eco-friendly profile, position aluminium heat sink profiles as the go-to choice for engineers and designers aiming for innovative cooling solutions in the evolving landscape of technology.

| Profile Type | Dimensions (mm) | Weight (kg/m) | Thermal Conductivity (W/m·K) | Fin Density (fins/inch) | Application |

|---|---|---|---|---|---|

| Flat Plate | 100 x 50 x 5 | 1.5 | 205 | 10 | LED Lighting |

| Extruded Profile | 120 x 40 x 10 | 2.0 | 210 | 8 | Computers |

| U-Channel | 150 x 30 x 15 | 2.5 | 215 | 12 | Power Modules |

| Angular Profile | 140 x 40 x 8 | 1.8 | 200 | 9 | Automotive |

| Finned Block | 200 x 75 x 20 | 3.0 | 220 | 15 | Industrial Equipment |

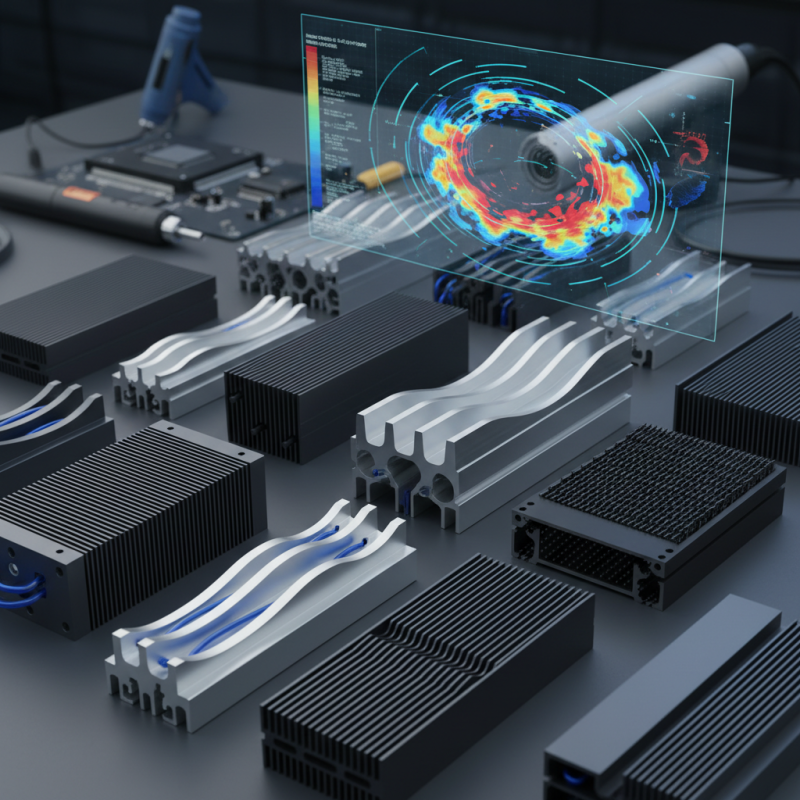

The latest trends in aluminum heat sink designs and materials are shaping the future of cooling solutions across various industries. As the demand for efficient thermal management continues to grow, manufacturers are focusing on innovative geometries and lightweight structures that enhance thermal performance while minimizing material usage.

Advanced extrusion techniques enable the creation of complex profiles that increase surface area for better heat dissipation, allowing for optimal efficiency in compact spaces.

Moreover, the integration of new materials and surface treatments is pushing the boundaries of traditional aluminum heat sinks. Enhanced anodizing processes and the use of thermally conductive coatings are becoming popular, providing added durability and improved thermal conductivity. These developments not only help to reduce costs through less material waste but also contribute to lighter and more robust cooling solutions that meet the needs of high-performance applications.

As technology progresses, the focus on sustainability is also influencing design choices, prompting manufacturers to adopt recycled aluminum and eco-friendly fabrication methods.

In recent years, the demand for efficient thermal management solutions has surged, particularly in sectors such as electronics, automotive, and renewable energy. The 2025 lineup of aluminum heat sink profiles stands out for their innovative designs and materials aimed at maximizing heat dissipation efficiency. A comparative analysis reveals that these profiles exhibit significant variations in thermal performance, largely driven by their surface area, geometry, and manufacturing technique. Profiles with enhanced surface textures or fins tend to outperform standard designs, promoting better airflow and increasing the effective heat transfer rate.

Additionally, the choice of alloy composition plays a crucial role in heat sink effectiveness. Aluminum alloys engineered for optimal thermal conductivity can significantly diminish hotspots within electronic components. Moreover, advanced fabrication methods, including extrusion and CNC machining, enable the creation of customized profiles tailored to specific cooling requirements. The findings suggest that, as technology advances, the interplay of design and material science will continue to shape the efficiency landscape of heat dissipation solutions, making it essential for engineers to stay informed about the latest developments in aluminum heat sink technology.

In the realm of thermal management, the standards and regulations governing aluminum heat sinks are pivotal for ensuring safety and efficiency. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) provide guidelines that dictate the minimum performance criteria for heat dissipation applications. According to a recent industry report, adherence to these standards can enhance the thermal conductivity of aluminum heat sinks by 20-30%, thereby significantly improving the cooling efficiency of electronic devices.

Moreover, environmental regulations, such as the European Union’s RoHS directive, which limits hazardous substances, have spurred innovation in the design and manufacturing of aluminum heat sinks. Recent data indicate that manufacturers employing sustainable practices and complying with these regulations have not only reduced their environmental impact but also enjoyed a 15% increase in product acceptance in eco-conscious markets. This trend underscores the importance of aligning product design with regulatory requirements to meet consumer demand while maintaining optimal cooling solutions for various applications.

The advancements in aluminum heat sink technology are propelling the industry toward more efficient cooling solutions, essential for various applications ranging from electronics to industrial machinery. According to a recent report by MarketsandMarkets, the global heat sink market is anticipated to grow from USD 2.6 billion in 2020 to USD 4.0 billion by 2025, indicating a significant demand for innovative cooling solutions. This growth is largely driven by the increasing need for thermal management in compact electronic devices that generate high heat densities.

Future innovations are leaning towards the integration of advanced manufacturing techniques and materials. The introduction of additive manufacturing and microchannel technology is reshaping traditional heat sink designs, enabling more effective thermal conductivity and reduced weight. A study by ResearchAndMarkets highlights that optimizing the surface area and minimizing thermal resistance are crucial trends that can enhance efficiency in thermal management systems. These innovations not only improve cooling performance but also contribute to resource sustainability by reducing material waste during production. As research continues, the focus will undoubtedly shift toward developing smarter and more adaptable heat sink profiles capable of meeting the dynamic needs of modern thermal management systems.